Understanding Digital Twins with Altair Solutions

The term "digital twin" is evolving. In this post we walk through Altair Engineering solutions that directly aid in a modern digital twin deployment.

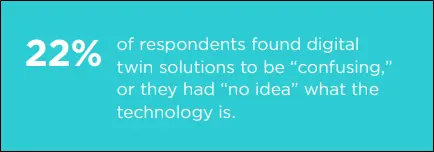

The concept of a "digital twin" has been around for a while but has been ambiguous as to what the complete definition is. According to the Altair Global Survey from 2022 (Fig 1), 22% of participants felt the concept is confusing. A simple definition of a digital twin is a virtual model of a physical object, process, or system. On its surface, that doesn’t seem complex, and can be anything from a CAD model to a Six Sigma process. In this post, our goal is to define how we define this concept and explain how Altair Engineering solutions can aid in this process.

Fig 1: Response from participants in 2022 Global Survey from Altair

Fig 1: Response from participants in 2022 Global Survey from Altair

What is a Digital Twin?

A digital twin is essentially a bridge between the physical and digital worlds. By creating a dynamic digital representation of a physical object or system, businesses can simulate, monitor, and control their counterpart without the constraints of the physical world. This enables engineers to understand not just how products and processes are performing but also how they will perform under various conditions.

To further differentiate – computer aided engineering (CAE Simulation) would be a virtual representation of a single step in a larger digital twin system-oriented process.

The applications for digital twins are vast and varied, including everything from optimizing the performance of complex machinery to enhancing the sustainability of buildings and urban infrastructures.

The Role of Altair Engineering Solutions in Digital Twins

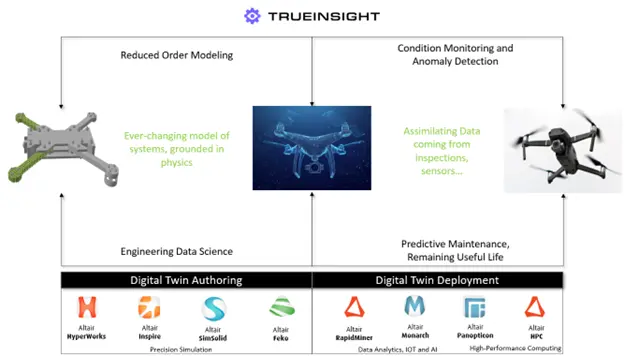

Altair Engineering offers a suite of software solutions that facilitate the creation and management of digital twins. These solutions include tools for simulation, data analytics, and high-performance computing, which are critical for developing accurate and dynamic digital twins.

Altair's portfolio and licensing model is designed to give more users the ability to handle complex data sets and perform advanced simulations. Users purchase Altair Units, which act as a currency to check out any of the software solutions I am going to talk about in this post. No need to purchase a license for each user and each software.

The Altair solutions really break down into three main categories when it comes to digital twins: Advanced Simulation, Data Analysis and High-Performance Computing.

Fig 2: A digital twin example using a quadcopter and Altair solutions.

Fig 2: A digital twin example using a quadcopter and Altair solutions.

Advanced Simulation and Design Capabilities

Using Altair's simulation software, such as Altair HyperWorks, Altair Inspire any of the Electrical/IOT or Mechanical Engineering simulation tools in the portfolio, users can create detailed models, incorporating the physics of real-world applications, material properties, and environmental factors. By simulating different scenarios, engineers can predict how their design would respond to different conditions and adjust the design accordingly.

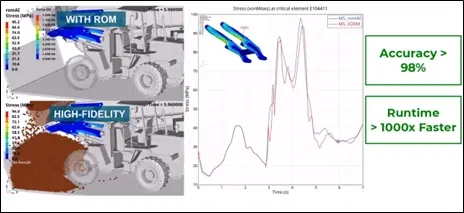

Running engineering simulation for each potential real-world scenario is time-consuming and can be resource draining. Digital twins with Altair use reduced order models (ROMs), which are essentially simplified versions of more detailed models. These ROMs significantly reduce the computational resources needed to get valuable insights from these simulations. Altair recently introduced Altair romAI, which allows users to combine AI technology with reduced order models.

Fig 3: RomAI example with results

Fig 3: RomAI example with results

The model-based systems engineering (MBSE) solution within the portfolio, includes Altair Embed for embedded systems development, Altair Twin Activate for system model simulation, and Altair Compose for math calculations and programming. These tools allow users to transition from individual product simulation into a multidisciplinary system or process analysis.

Real-time Data Analysis

Altair RapidMiner and Altair Knowledge Studio are data science platforms that provide an integrated environment for data preparation, machine learning, deep learning, text mining, and predictive analytics. It is instrumental in the initial stages of the digital twin process, where vast amounts of data from various sources need to be analyzed to create accurate and dynamic models of physical assets.

A digital twin is not just a static model; it's continuously updated with real-time data to reflect the current state of its physical counterpart. Altair Panopticon allows for the visualization and monitoring of this data in real-time. This capability enables the digital twin to stay accurate over time and provides immediate insights into the asset's performance, maintenance needs, or any changes in its operating conditions.

Use Case in Digital Twin:

Predictive Maintenance: By analyzing historical and real-time data from sensors on a physical asset, RapidMiner, Panopticon and Knowledge Studio can help users predict when a component is likely to fail, allowing for maintenance to be scheduled proactively, reducing downtime and operational costs.

High-Performance Computing

The Altair high-performance computing solution, Altair HPCWorks, provides the computational horsepower required to simulate, analyze, and optimize complex models in real time. HPCWorks includes options to run single or multi-cluster options, which allows users to optimize their processes depending on project needs. Whether it's predicting equipment failure before it happens, optimizing manufacturing processes, or simulating scenarios in a virtual environment, HPC ensures that the digital twin process is seamless, efficient, and scalable.

With the latest release of HPCWorks, a new AI-powered job submission tool, Altair Access, is included. It uses historical data, project inputs and file mining to predict job behavior.

Real-World Applications

The applications of digital twin technology are widespread. For a few of the more common examples:

Manufacturing: Digital twins optimize production lines and supply chains, making them more efficient and flexible. Altair’s portfolio includes manufacturing simulation tools for metal casting and forming, metal and polymer extrusion, injection molding and additive manufacturing all of which integrate into a digital twin process with Altair.

Automotive and Aerospace: These deployments can accelerate the development of new vehicles/aircraft by simulating vehicle dynamics under various conditions and predicting maintenance schedules.

Energy Sector: Deploy digital twins designed for wind farms and electrical grids to optimize output and distribution; and assist in designing sustainable buildings and managing resources more efficiently.

One thing is clear, digital twins are here to stay with most projections expecting between 25-30% growth in deployments over the next five years. If you have any questions or want to learn more about this technology, let us know.

Fig 4: AI Generated image of future manufacturing floor with digital twin overlay

Fig 4: AI Generated image of future manufacturing floor with digital twin overlay