What is Altair Inspire PolyFoam?

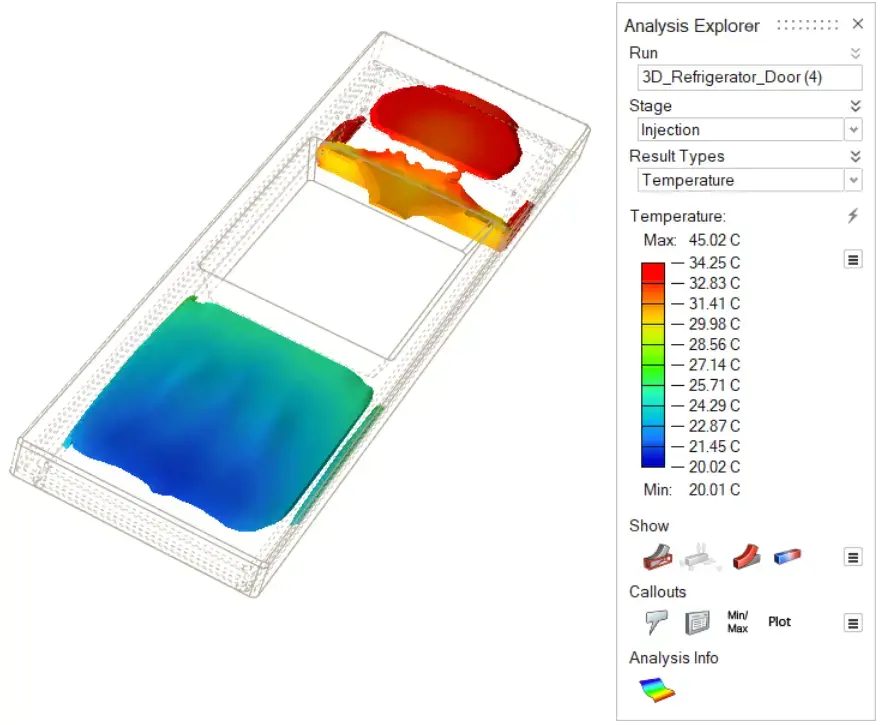

Altair Inspire Polyfoam allows users to simulate the process of foam expansion for polyurethane foams, both rigid and flexible. The built-in five step workflow allows users to easily evaluate manufacturability of their product while reducing manufacturing defects like shrinkage and porosity. Process simulations include injection, filling, foaming, curing, and cooling.

Key Capabilities

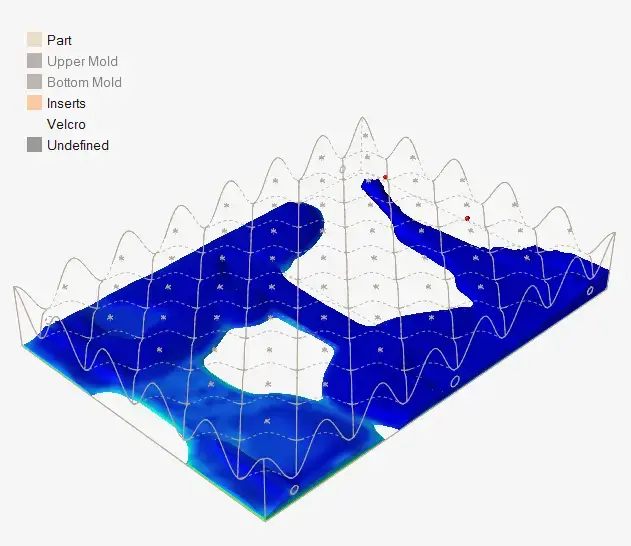

- Detect manufacturing defects early in the development cycle such as: air traps, shrinkage, porosity, weld lines and turn-up

- Create initial mold with components based on imported 3D parts

- Test and optimize different process configurations - fixed, moving or sequential gates and nozzles

- Simulate the injection of multiple foams within a single mold