What is Altair Inspire Print 3D?

With a focus on design optimization and simulation, Altair Inspire Print3D enables users to create and print functional prototypes, parts, and assemblies with superior performance and efficiency. Altair Inspire Print3D also offers access to a range of advanced materials and printing technologies for a customizable and streamlined printing experience.

Key Capabilities

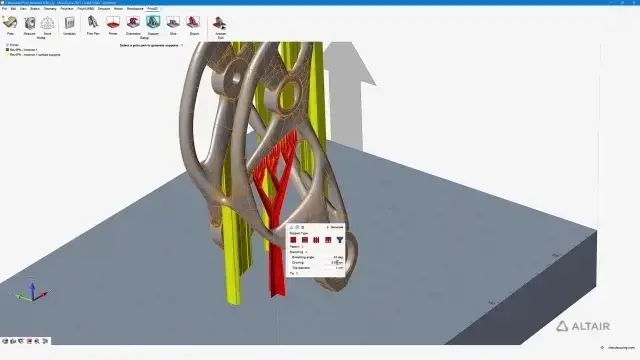

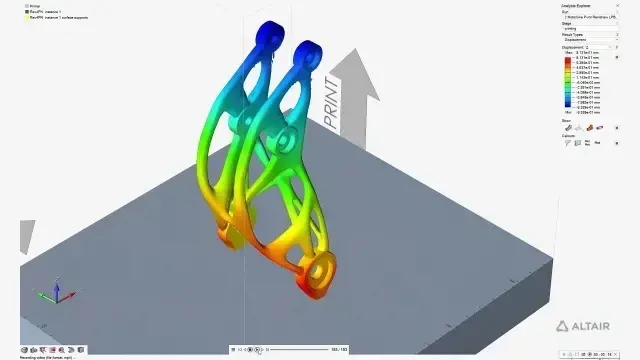

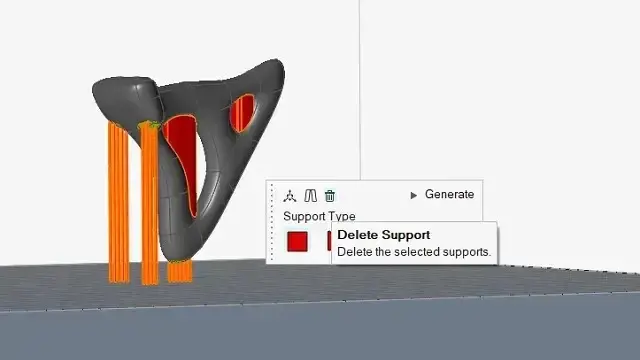

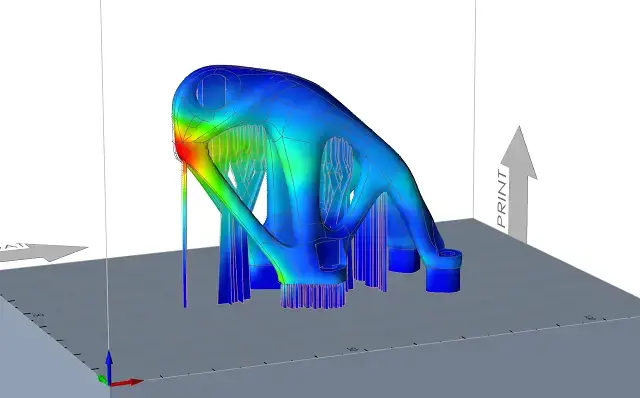

- Understand potential defects in the additive manufacturing process like deformation, excessive heating and delamination.

- Take advantage of a vast material library of additive manufacturing printers and materials.

- Simple, intuitive ribbon style interface for short learning curve and quick results.

- Slice and export file accepted by additive manufacturing printers.