What is Altair Inspire Mold?

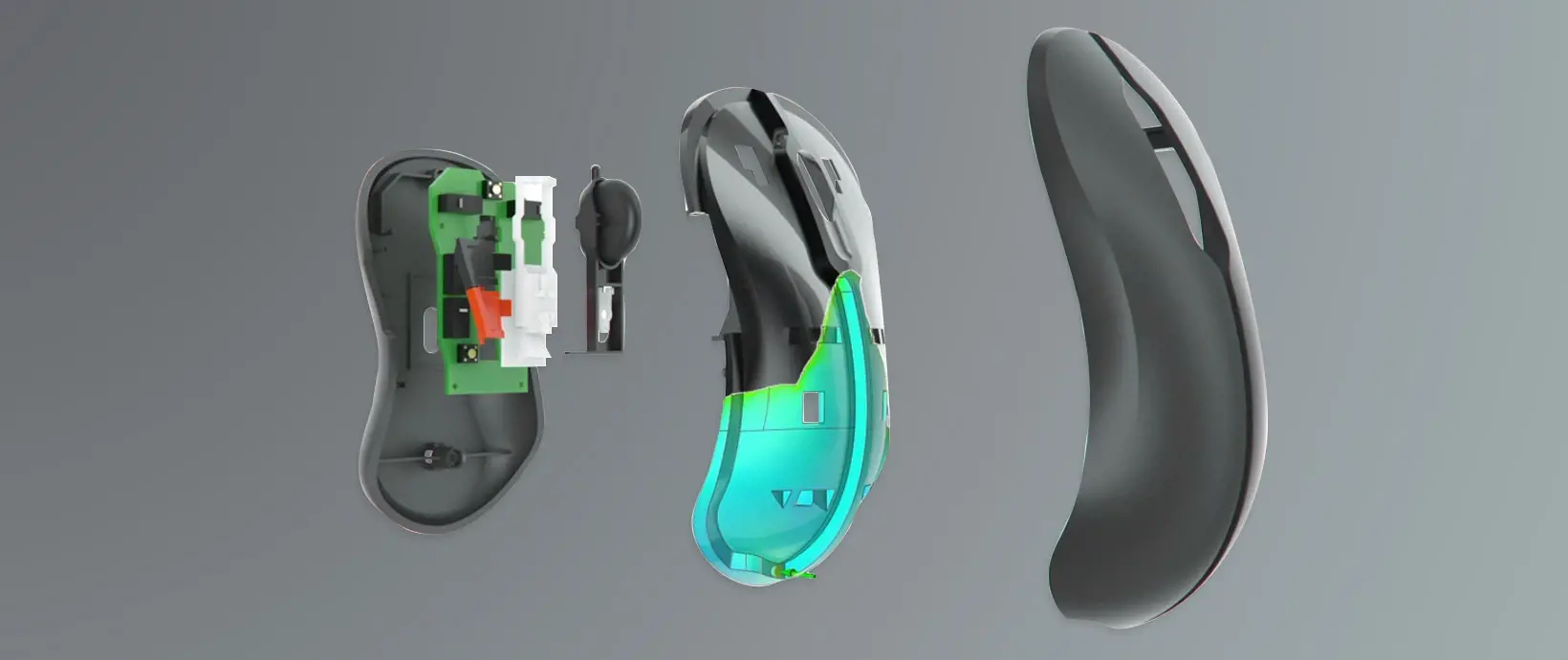

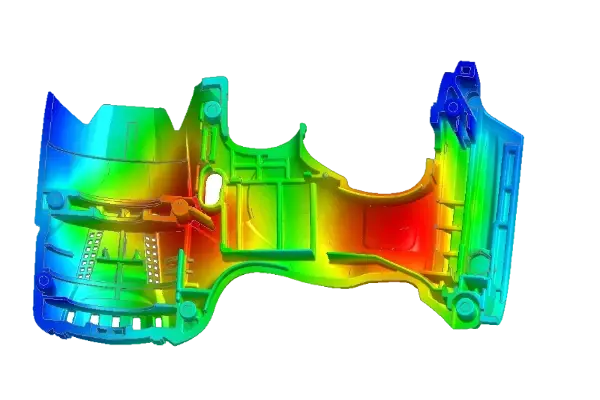

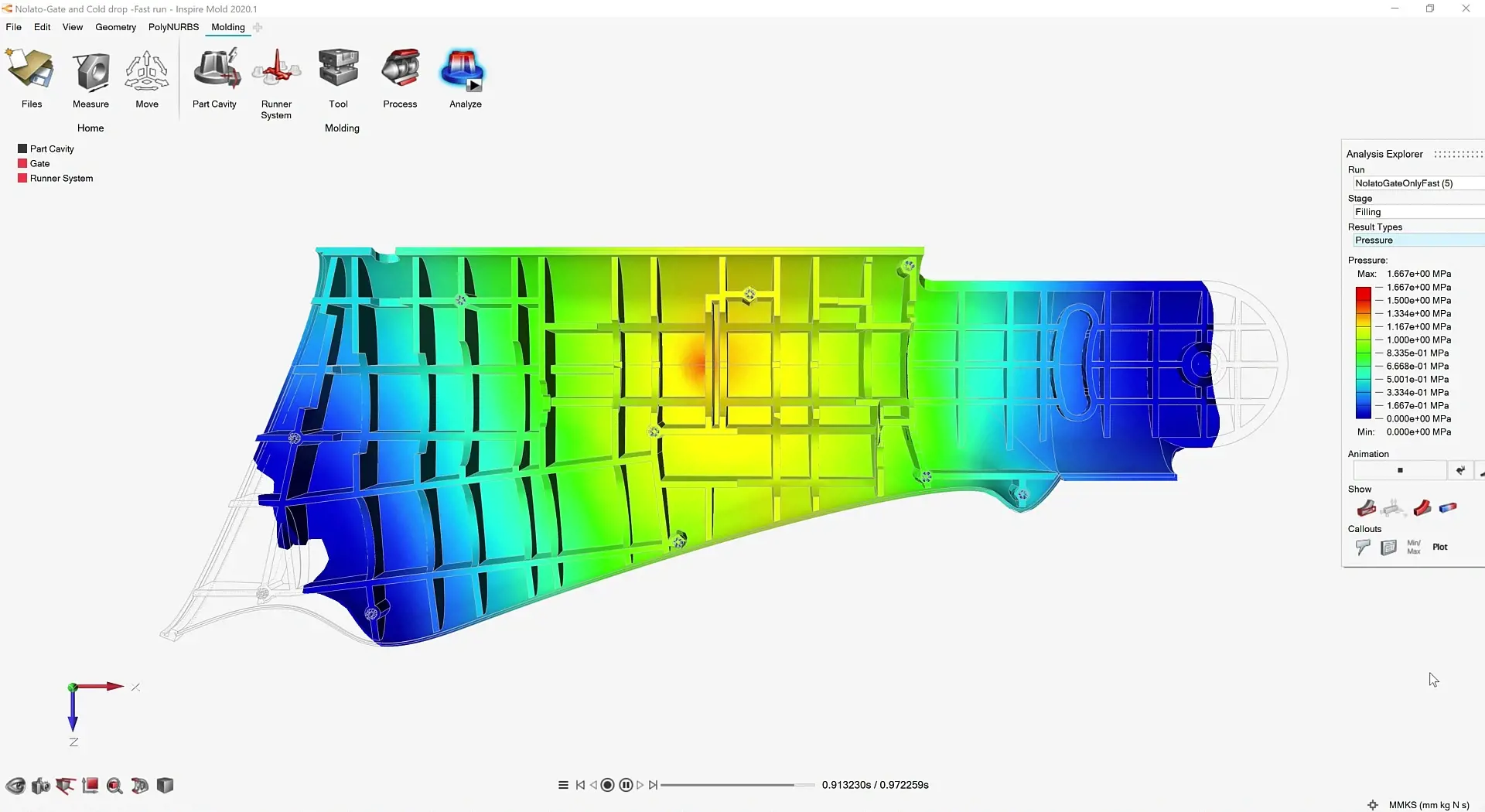

Inspire Mold is an integrated tool to analyze plastic injection molding processes. From mold creation to filling, packing, cooling and warpage simulation. A simple workflow helps users avoid common injection molding defects such as warping, short shots and sink marks. Inspire Mold adds to an already robust manufacturing analysis solution from Altair.

Key Capabilities

- Generate mold designs and mold configurations including runner systems, gates and other mold components

- Filling, packing, cooling and warpage simulations

- Understand manufacturing defects like: air traps, weld lines, jetting and hesitation

- Simulate fiber orientation for reinforced parts