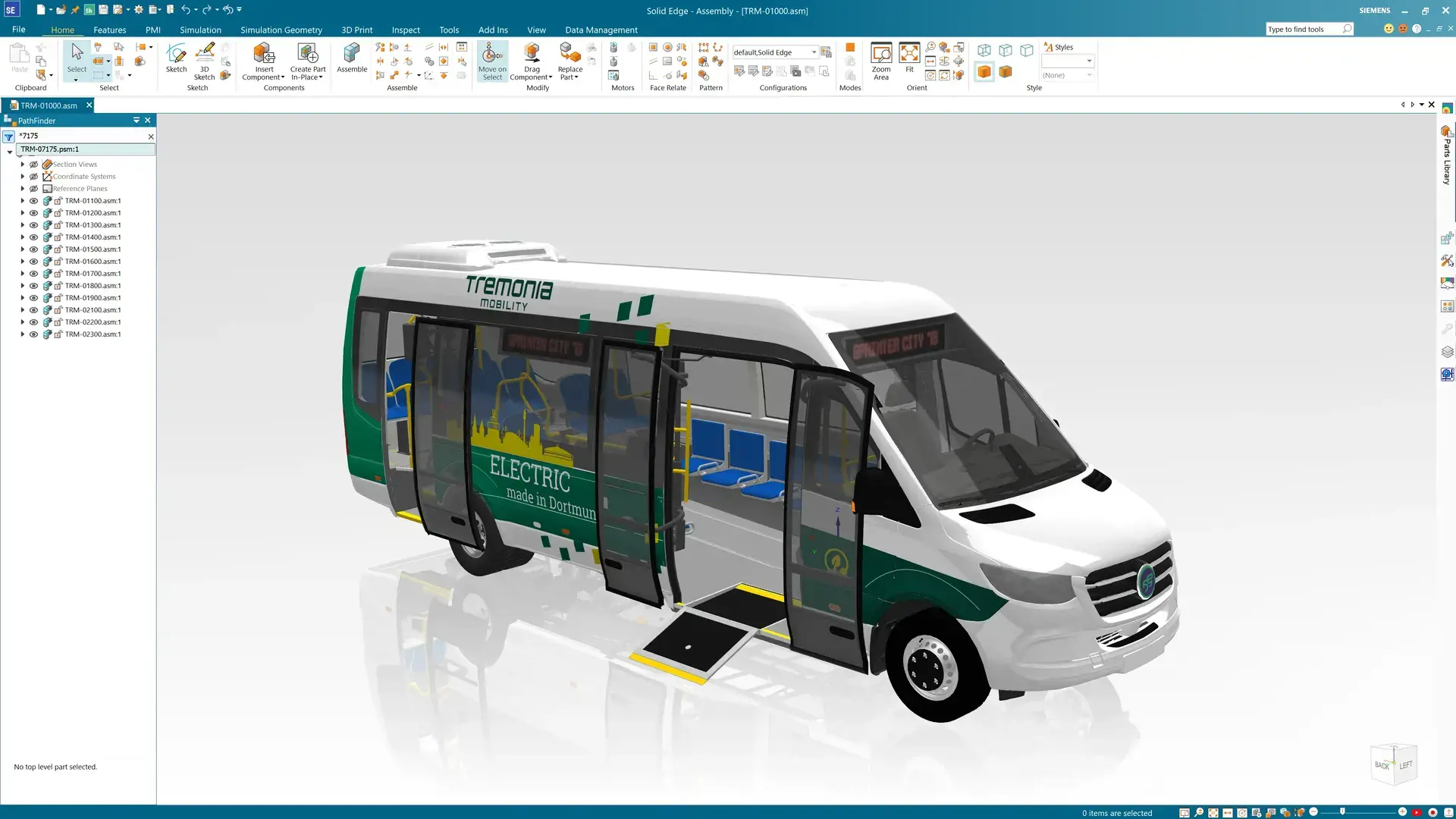

Siemens Solid Edge: Professional 3D CAD for Engineering Teams

Design, validate, and prepare products faster with synchronous technology and modern 3D CAD workflows.

What is Siemens Solid Edge?

Professional 3D CAD for Engineering Teams

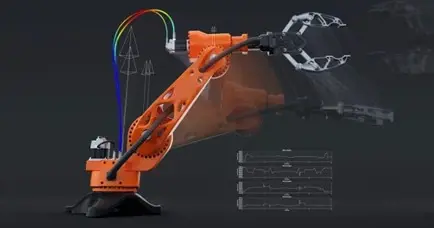

Siemens Solid Edge is a professional 3D CAD software designed for engineers and design teams who need fast, flexible, and reliable product development tools. It enables users to create, simulate, and prepare products for manufacturing more efficiently, combining intuitive modeling workflows with Synchronous Technology to allow rapid design changes without the limitations of traditional history-based CAD systems.

Why Choose Siemens Solid Edge

Flexible 3D CAD capabilities built for modern engineering teams

Key Capabilities of Siemens Solid Edge

Engineering-ready features, enhanced with expert implementation and support.

Expert Support Beyond the Software

With TrueInsight, your Siemens Solid Edge implementation goes far beyond software licensing.

Our engineering-focused specialists help design teams get real value from Solid Edge—optimizing modeling workflows, accelerating design changes, and ensuring best practices across the entire product development lifecycle.

We work alongside your engineers to reduce rework, improve design quality, and shorten time-to-market by applying Solid Edge effectively to real-world mechanical and manufacturing challenges.

Learn More About Product Design with Siemens Solid Edge

In-depth articles, guides, and best practices focused on Siemens Solid Edge for 3D CAD design, synchronous modeling, and manufacturing-ready engineering workflows.

Frequently Asked Questions About Siemens Solid Edge

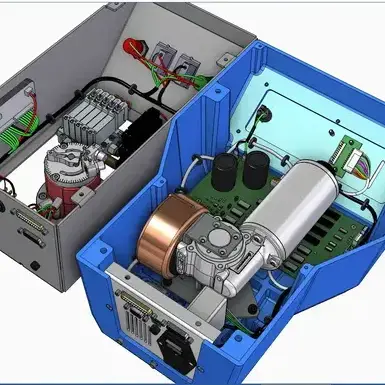

Siemens Solid Edge is a professional 3D CAD software used for mechanical design, product development, and manufacturing preparation. Engineers use it to create parts and assemblies, validate designs, and prepare models for production using integrated CAD, simulation, and CAM tools.

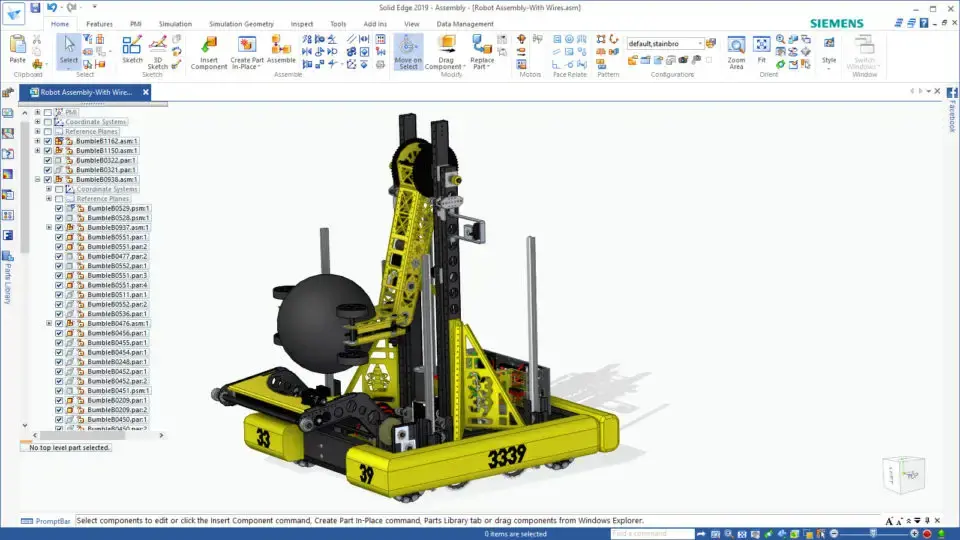

Yes. Solid Edge is widely used for mechanical design, including part modeling, large assemblies, sheet metal, frames, weldments, piping, and surface modeling. Its tools are designed to handle real-world engineering complexity efficiently.

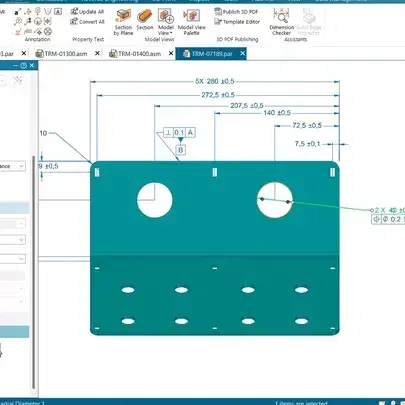

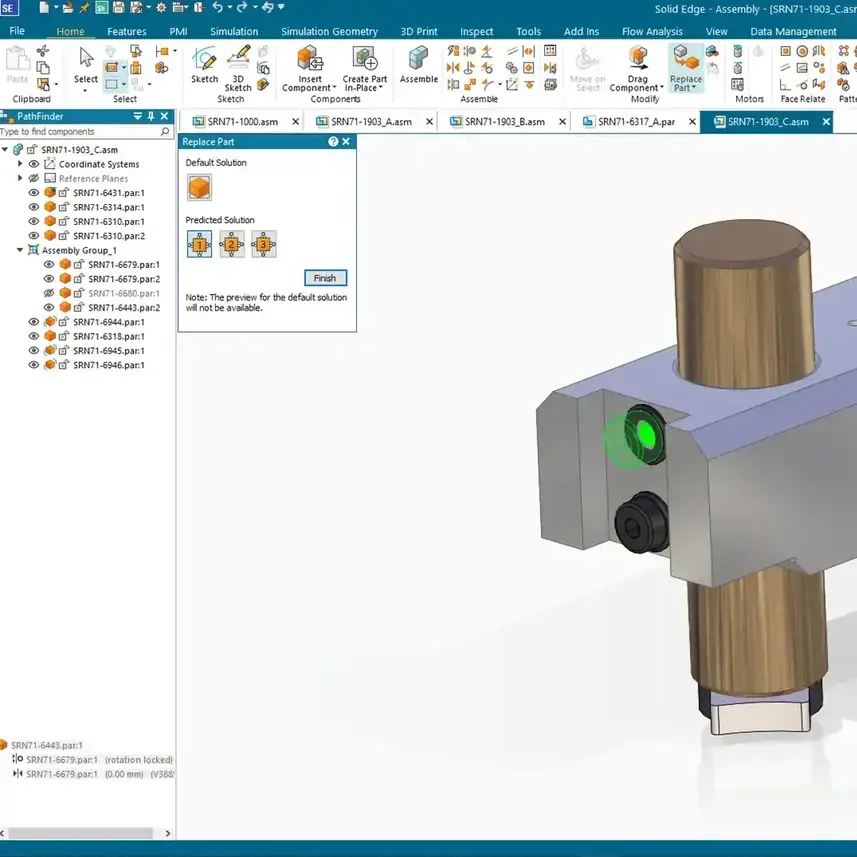

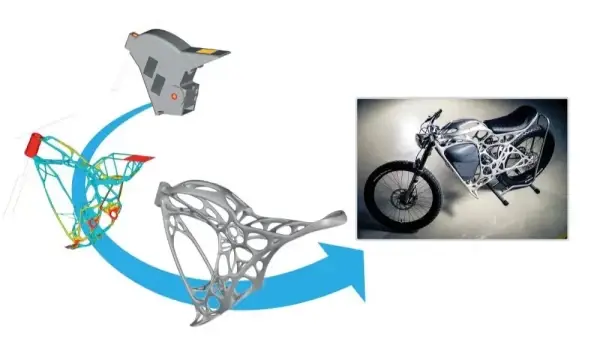

Synchronous Technology is Solid Edge’s unique hybrid modeling approach that combines direct modeling flexibility with parametric control. It allows engineers to edit geometry instantly—without rebuilding feature histories—making it ideal for late-stage changes and imported CAD data.

Unlike traditional history-based CAD systems, Solid Edge uses Synchronous Technology, enabling faster design changes and greater flexibility. It also integrates CAD, simulation, and manufacturing workflows in a single environment, reducing the need for additional tools.

Yes. Solid Edge is built to manage large assemblies and complex products efficiently, with performance optimization tools that allow engineers to work smoothly even with thousands of components.

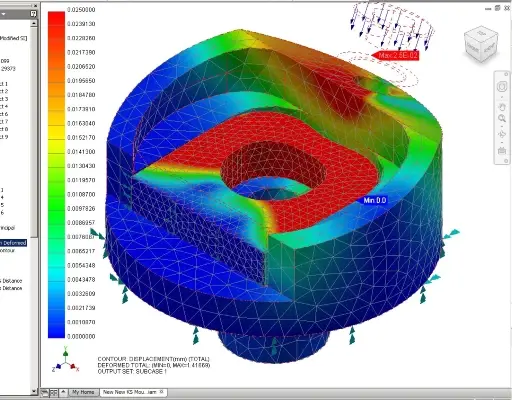

Yes. Solid Edge includes built-in simulation capabilities, such as structural, thermal, and motion analysis, allowing engineers to validate designs early and reduce costly errors before manufacturing.

Ready to Take the Next Step with Siemens Solid Edge?

We look forward to partnering with you to find the best solution to your challenges!

Contact Us Get Pricing