Enterprise CAD & Product Development with Siemens NX

A powerful computer-aided design (CAD) solution for 3D modeling, simulation, and integrated product development

What Is Siemens NX?

Advanced CAD software for integrated product development and engineering workflows

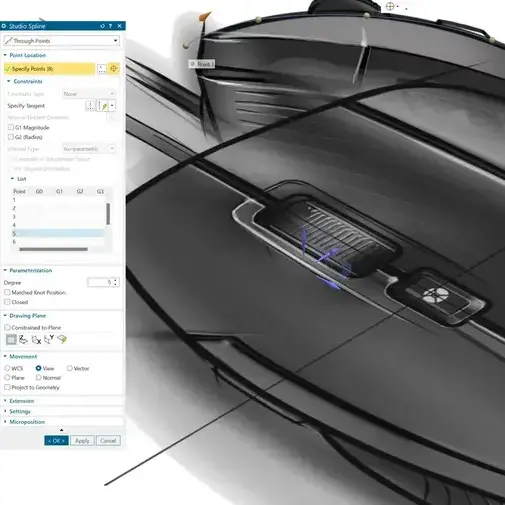

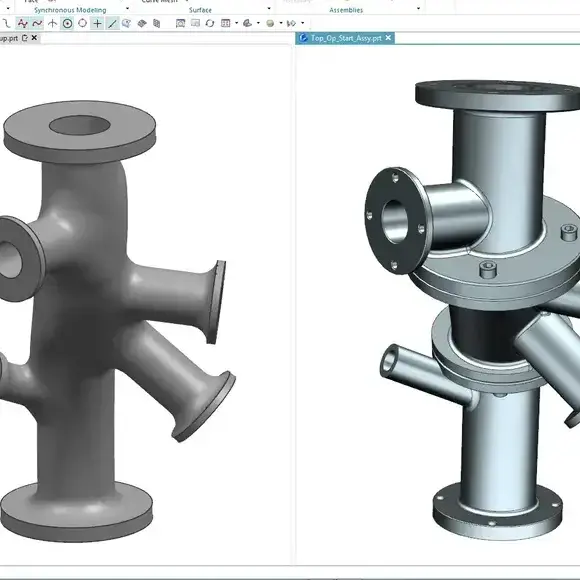

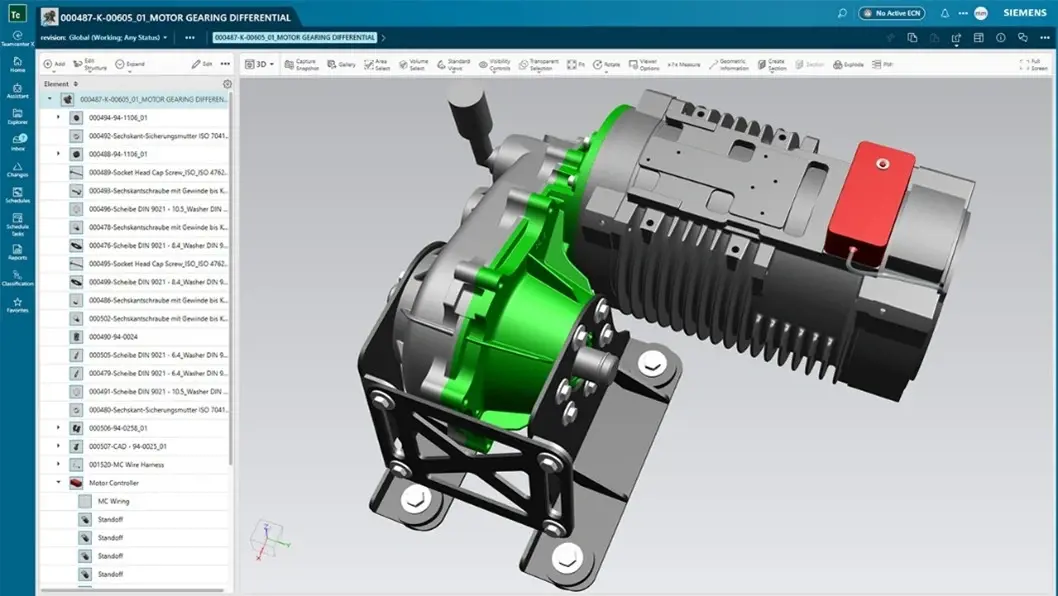

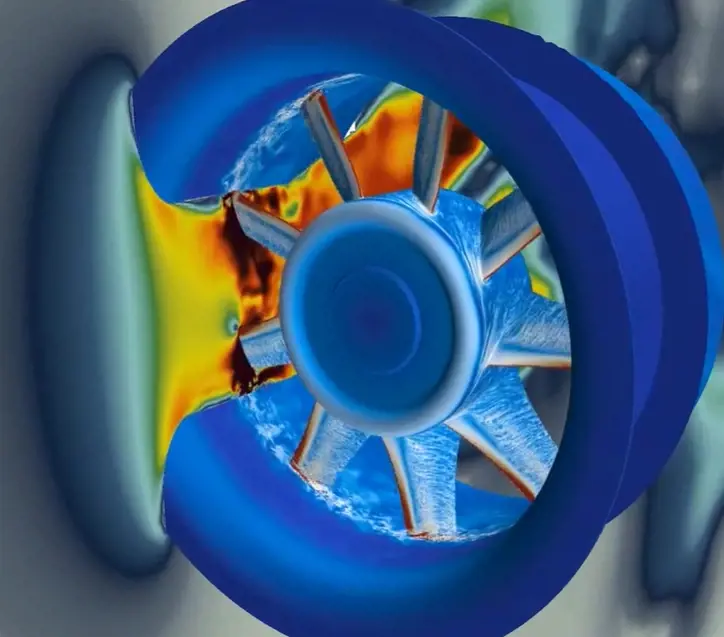

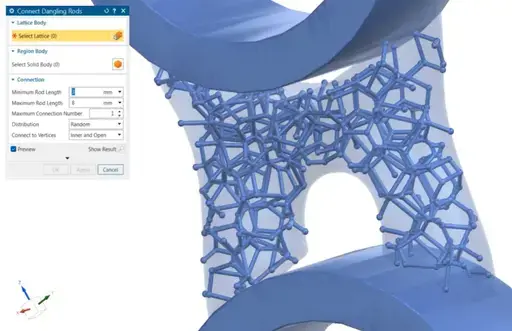

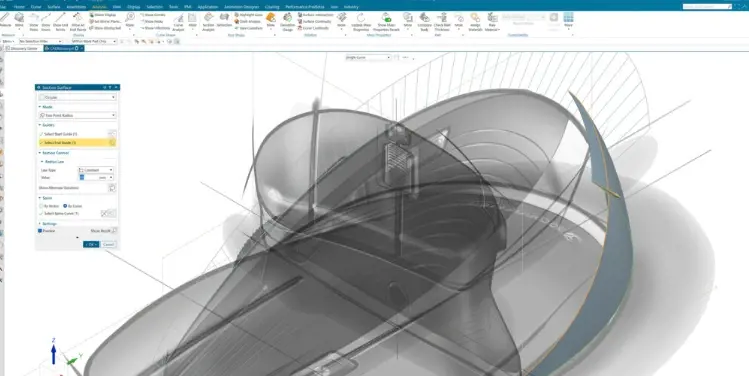

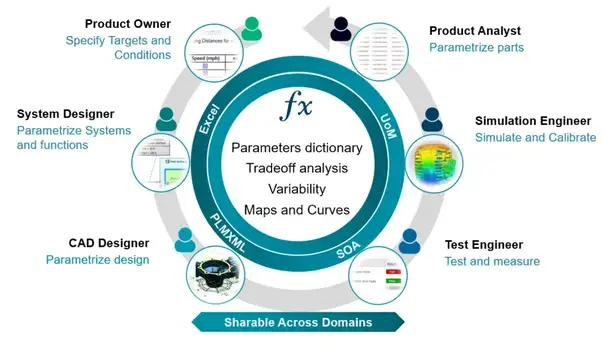

Siemens NX is an advanced CAD software and product development platform for engineers and designers working on complex products. It brings together 3D modeling, parametric and direct design, simulation and engineering analysis, and integrated product lifecycle workflows in a single environment.

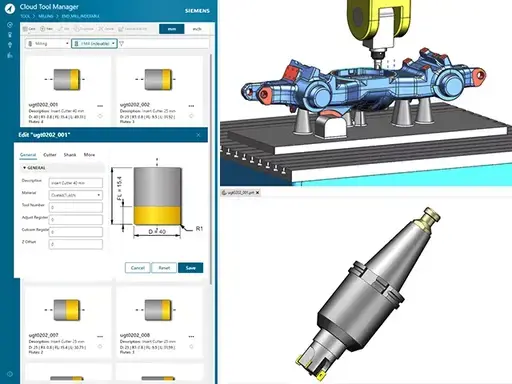

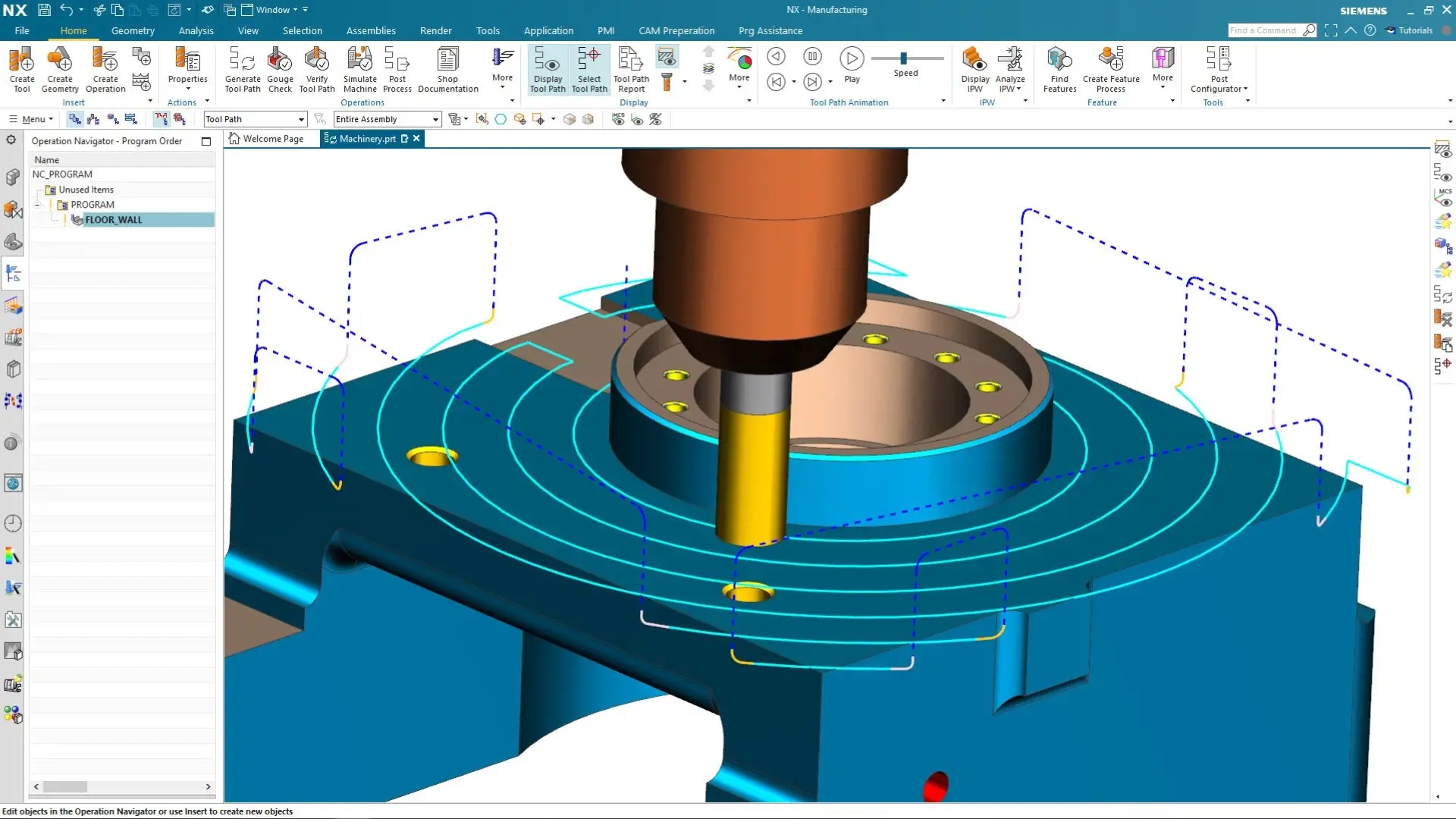

Core Capabilities of Siemens NX

Integrated CAD, CAM, and advanced engineering workflows in a single platform

Key Capabilities of Siemens NX

End-to-end CAD, CAM, and CAE capabilities for complex product development and digital manufacturing.

Expert Support Beyond the Software

With TrueInsight, your Siemens NX implementation goes far beyond software licensing.

Our engineering-focused experts provide fast response times and hands-on guidance across the entire product development lifecycl , from CAD modeling and design validation to advanced simulation, manufacturing workflows, and digital thread implementation. We help engineering teams reduce rework, validate designs earlier, and apply Siemens NX effectively to real-world product development and manufacturing challenges.

Learn More About Product Development with Siemens NX

In-depth articles, tutorials, and best practices focused on Siemens NX for CAD design, simulation, manufacturing, and end-to-end product development workflows.

Frequently Asked Questions About Siemens NX

Siemens NX is used for advanced computer-aided design (CAD), engineering simulation (CAE), and manufacturing (CAM) within a single, integrated product development environment. Engineering teams use NX to design, validate, and manufacture complex products while maintaining a continuous digital thread across the entire lifecycle.

Unlike standalone CAD systems, Siemens NX integrates design, simulation, and manufacturing workflows in one platform. This reduces data translation, supports early design validation, and enables consistent digital twin and digital thread workflows across product development stages.

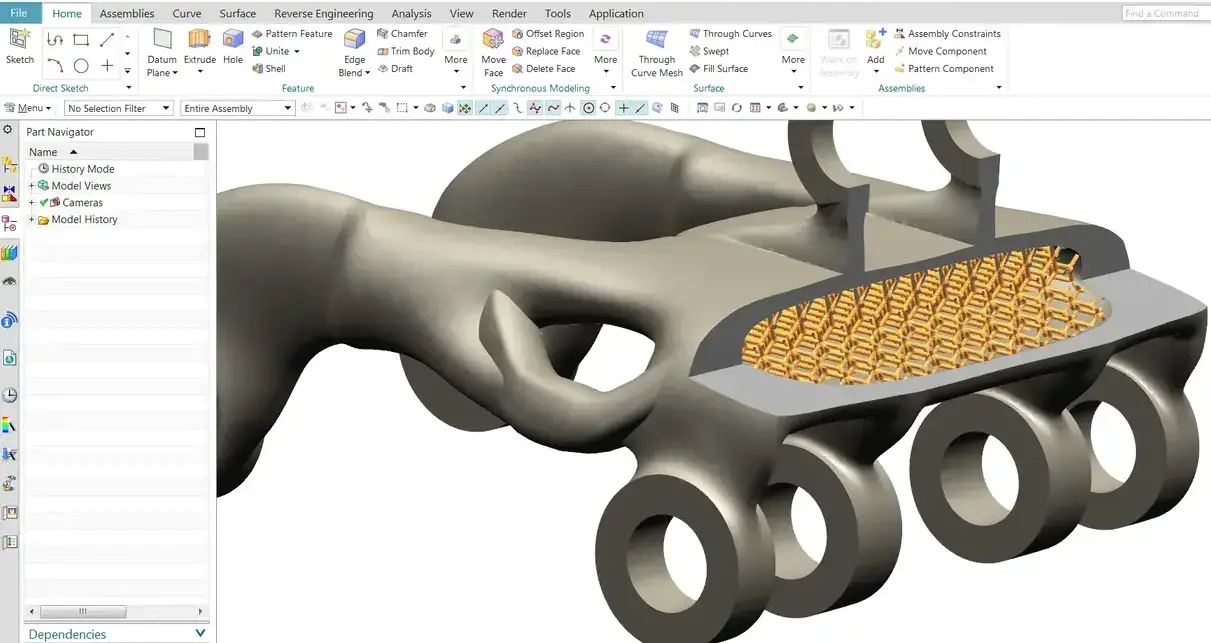

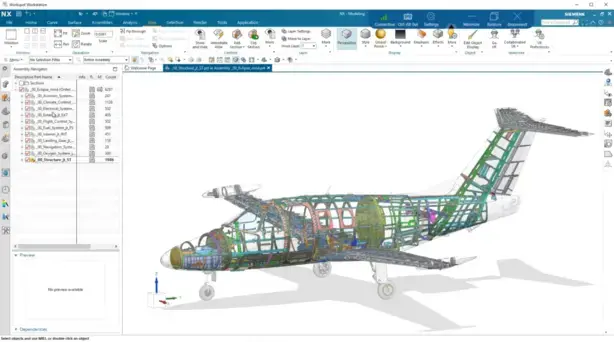

Yes. Siemens NX is built for enterprise-scale engineering and supports large assemblies, complex geometries, and high-performance modeling workflows commonly found in aerospace, automotive, industrial equipment, and advanced manufacturing environments.

Yes. Siemens NX includes integrated simulation and validation capabilities that allow engineers to analyze structural, thermal, and motion behavior early in the design process, helping reduce physical prototypes and design rework.

Absolutely. Siemens NX provides integrated CAM tools for machining, additive manufacturing, and advanced manufacturing workflows, enabling a seamless transition from design to production without data loss.

Siemens NX is widely used in industries such as aerospace, automotive, industrial machinery, consumer products, energy, and high-tech manufacturing—especially where complex products, digital twins, and end-to-end product development are required.

Explore Siemens NX capabilities

We look forward to partnering with you to find the best solution to your challenges!

Contact Us Get Pricing