What is Siemens CAM?

Siemens CAM makes the leap from design to manufacturing simple. Instead of juggling separate tools, you can go from your CAD model straight to a ready-to-run machining program in one connected platform. It’s built inside Siemens NX, so everything stays consistent and accurate, no file conversions, no headaches.

Key Capabilities

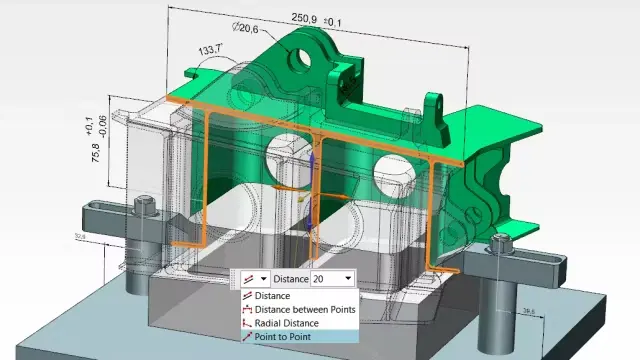

- Integrated CAD/CAM Environment

- Siemens CAM is fully integrated with Siemens NX, allowing seamless transition from design to manufacturing without data translation.

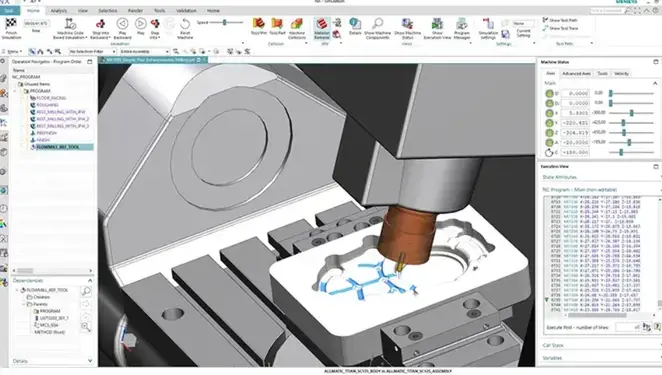

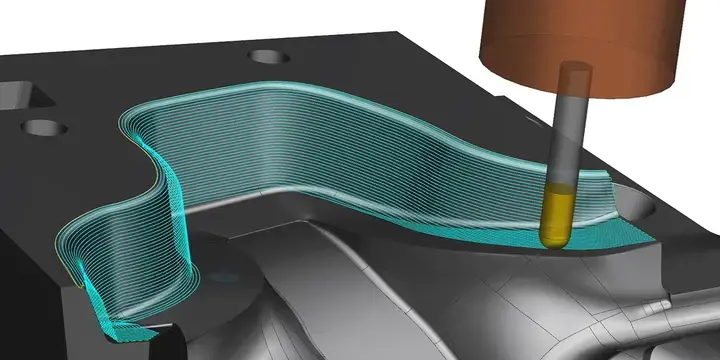

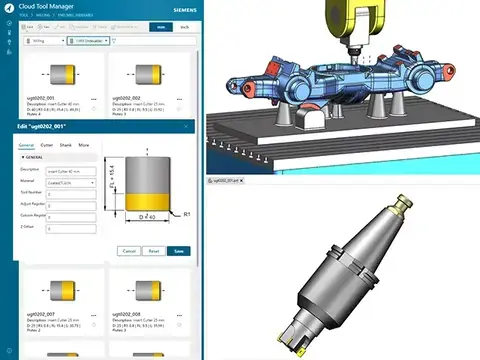

- Digital Twin of Machining

- Create a virtual machine environment to simulate, validate, and optimize toolpaths before production.

- Additive and Hybrid Manufacturing

- Support for additive manufacturing workflows, including deposition and hybrid machining.

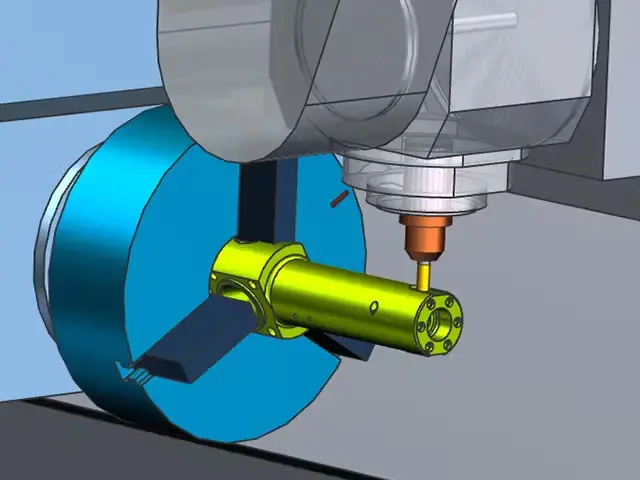

- Robotics and CNC Integration

- Directly program industrial robots and CNC machines, reducing setup time.

Ready to Take the Next Step?

We look forward to partnering with you to find the best solution to your challenges!

Contact Us Get Pricing