TrueInsight

Siemens/Altair Channel Partner

Menu

Lightweighting and Optimization

Lightweighting and Topology Optimization

Lightweighting has been used in specific sectors for decades, but has recently seen widespread adoption across all industries.

There are endless benefits to lightweighting designs including: Improved fuel efficiency, material scrap and use savings or better structural performance of the design. Altair has the most complete solution portfolio for accomplishing these tasks.

Altair for Lightweighting and Optimization

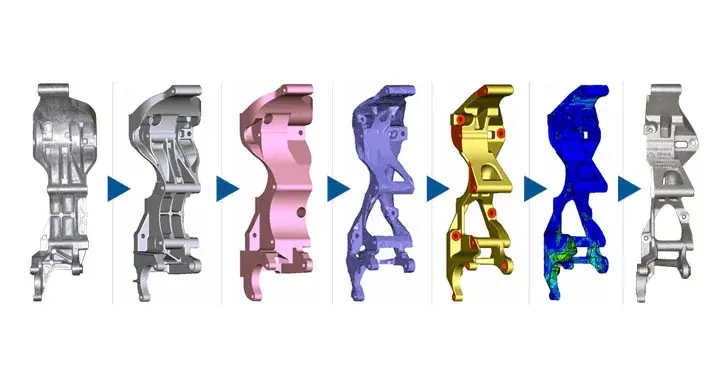

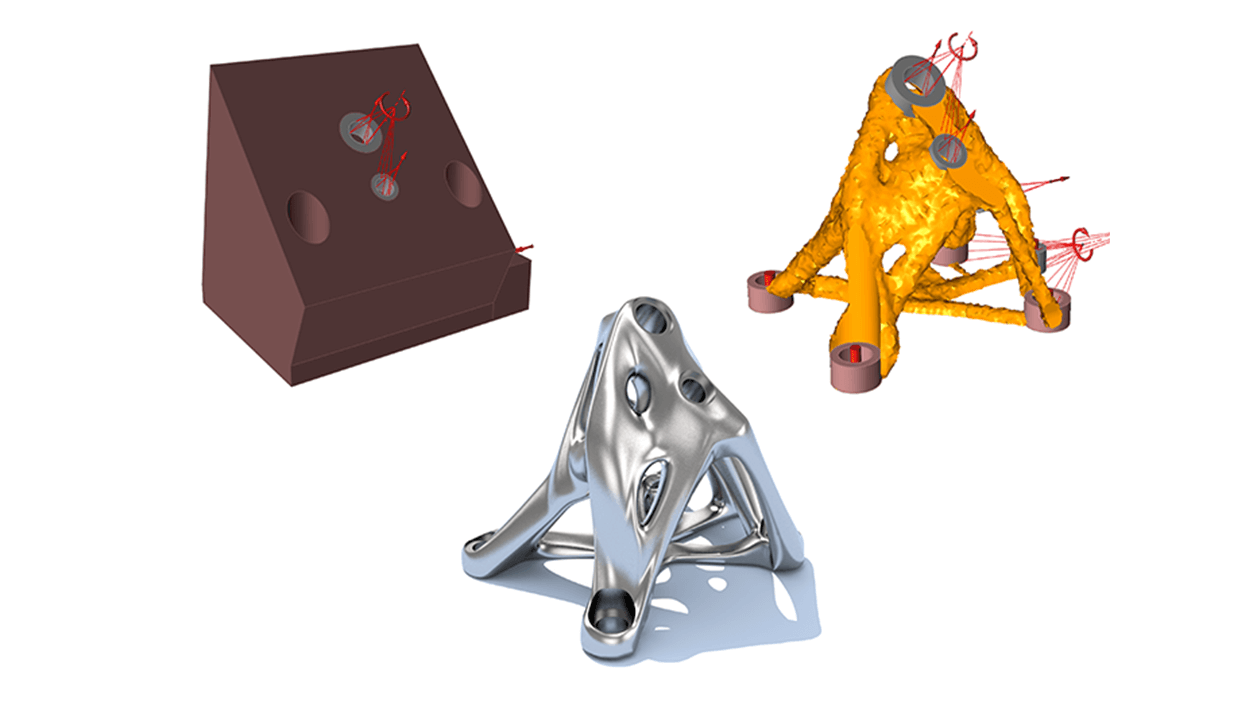

Optimization

Optimization creates more efficient structures by taking into account design criteria such as expected loads, material and environments. One of the leading technologies for topology optimization for the last twenty years has been Altair OptiStruct™. Altair also built upon the Altair OptiStruct™ technology to create Altair Inspire™, which uses the same topology optimization capabilities, but in a new user interface. Users can understand challenges like topology optimization, but also, topograhy, gauge, lattice and multi-physics analysis using Altair HyperStudy™.

Material Availability

Using the Altair Material Datacenter, users have access to one of the widest material databases available. This datacenter is available currently as a cloud-based application, but will soon be integrated into the tools users know and love like Altair SimLab™, Inspire Product Platform and HyperWorks Product Platform.

Altair's focus on having the widest material database ensure users get the most reliable results possible.

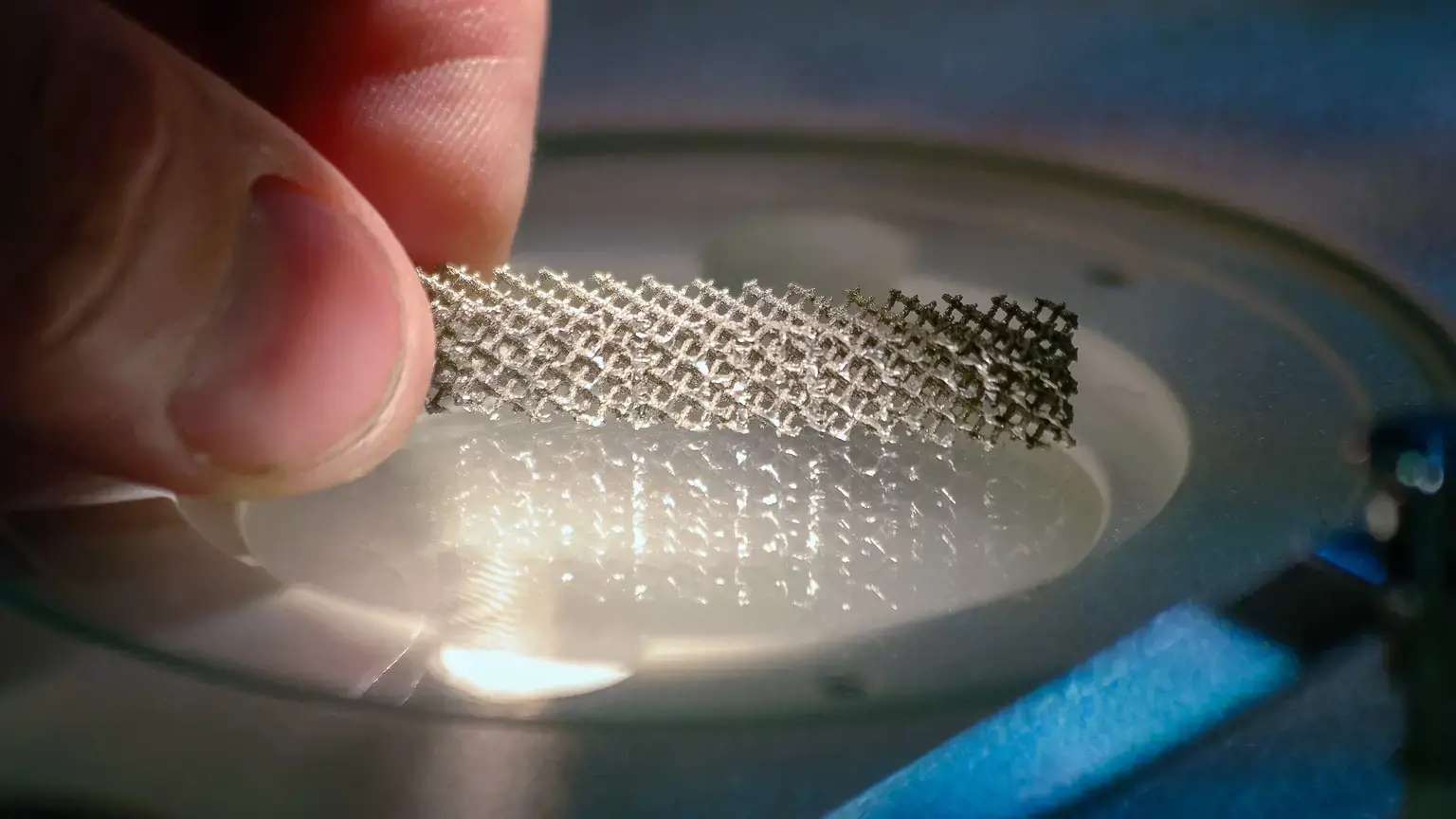

Additive Manufacturing Support

3D Printing has allowed designers to think about product development in different, innovative ways. One way it has changed the industry is the idea of how products are manufactured. Whether its lightweighting parts by printing hollow or sparse centers, or designing using lattice structures to reduce material cost, Altair has a unique toolset to help designers understand how to take advantage of this flexibility.

Users can also check out Inspire Print 3D to optimize their additive manufacturing workflows.