Altair Engineering Simulation Suite: Your Top Questions Answered

We answer some of your most common questions about the Altair Engineering Simulation Suite of tools.

The Altair Engineering portfolio has a lot of solutions, which naturally lead to questions. We’ve gathered some of the most common questions we hear about Altair’s simulation tools and answered them in one place.

Q1: What is the Altair Engineering Simulation Suite?

A: The Altair Simulation Suite is a comprehensive collection of CAE tools designed to support product development from concept through manufacturing. The biggest strengths of the suite lie in ability to work within most existing workflows, and the licensing allows users to use many of these solutions without purchasing a named license for each user. It includes tools for:

- Preprocessing and Meshing (Altair HyperMesh, SimLab)

- Structural Analysis (Altair OptiStruct, SimSolid, SimLab)

- Multiphysics (Altair SimLab, Feko, Flux)

- Fluid Dynamics (Altair AcuSolve, nanoFluidX, ultraFluidX)

- Motion and Kinematics (Altair MotionView, MotionSolve)

- Electromagnetics (Altair Flux, Feko)

- Manufacturing Simulation (Altair Inspire Cast, Form, Extrude, PolyFoam)

- Optimization and Generative Design (Altair Inspire, OptiStruct)

When combined, they form a very robust solution for anyone needing to do product validation at any step in their process.

Fig 1: Screenshots from various Altair simulation products

Q2: What's the difference between Altair Inspire and SimSolid?

A: Both tools are used early in the design process, but they can serve different purposes. In a previous post we talked about the differences between Altair Inspire, SimLab and SimSolid.

- Altair Inspire: Ideal for conceptual design, topology optimization, motion simulation, and lightweighting. It works directly with CAD and supports lattice generation, DfAM (Design for Additive Manufacturing, and traditional manufacturing validation for sheet metal, metal casting, injection molding, extrusion and polyurethan foam expansion. Inspire also includes the ability to run both FEA and CFD simulations in combination with the above studies.

- Altair SimSolid: Meshless structural simulation tool for evaluating large, complex assemblies in seconds or minutes. It doesn’t require geometry cleanup or meshing, making it perfect for rapid design iteration primarily while still in the design stage of the product development process.

To simplify: Use Inspire when you want to create better designs. Use SimSolid when you want to validate them quickly.

Q3: How does Altair handle meshing and geometry cleanup compared to traditional FEA tools?

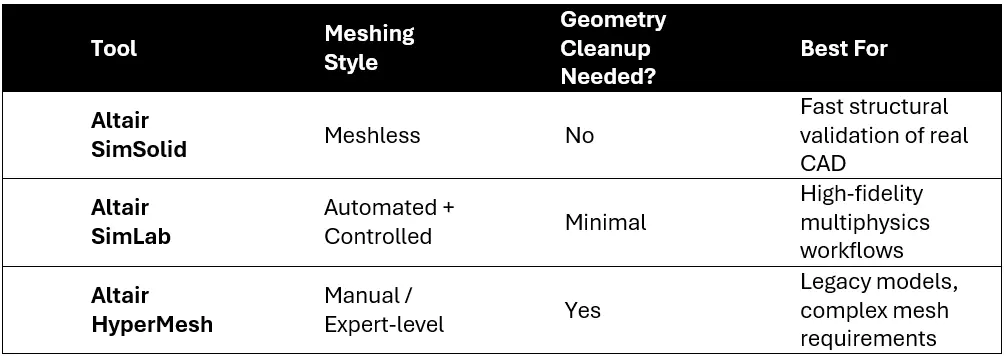

A: Altair offers multiple approaches:

SimSolid eliminates meshing and geometry cleanup altogether.

- It uses external approximation methods instead of traditional finite elements.

- Simulates directly on raw, uncleaned CAD geometry (including STL files), no simplification required.

- Handles large assemblies with bolts, welds, and contact conditions without user intervention.

SimLab bridges the gap between automation and control.

- Automates meshing based on feature recognition, like fillets, holes, contacts, and boundaries.

- Maintains associativity with CAD, so design changes update seamlessly.

- Offers advanced template-based workflows, which is great for repetitive processes like electronics cooling, drop tests, or motor simulation.

HyperMesh is Altair’s flagship pre-processor for traditional FEA.

- Offers complete control over mesh topology, quality, and element types.

- Supports complex meshing workflows including hexa-meshing, shell-solid transitions, midplane extraction, and more.

- Includes extensive tools for geometry cleanup, defeaturing, and repair, commonly used for imported STEP/IGES files.

Q4: What’s included with an Altair Units license?

A: The Altair Units licensing system is one of the most flexible in the industry. Instead of buying software per seat or per product, users purchase a pool of Altair Units, which can be used across the entire Altair product line, including simulation, AI, data analytics, and HPC tools.

- Shared across users: Everyone on your team draws from the same pool.

- Shared across tools: You’re not locked into a specific product.

- Recyclable: Units are released after use, so others can access them.

- Cross-domain: The same units can be used for simulation, data analytics, AI, high-performance computing (HPC), and more.

Fig 2: Graphic showing how Altair Units work

Q5: I work with additive manufacturing. What tools does Altair offer?

A: Altair has built up this part of their solution over the last few years and is one of the strongest offerings you can find. I will highlight two tools specifically; Altair Inspire and Altair OptiStruct.

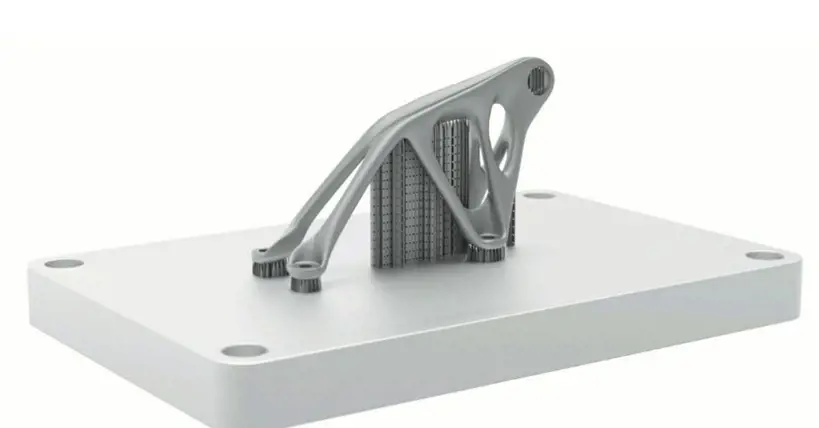

Altair Inspire: Generative Design & DfAM

Inspire allows users to design parts that take full advantage of additive manufacturing solutions.

- Topology Optimization: Remove unnecessary material based on real-world loading to create strong, lightweight structures.

- Lattice & Gyroid Structures: Automatically generate internal lattice or shell structures that are ideal for 3D printing.

- Manufacturing Constraints: Apply AM-specific constraints (e.g., overhang angle, symmetry, minimum thickness) during optimization to ensure the design is printable.

- Part Consolidation: Combine multiple components into a single printable part to reduce assembly time and increase strength.

Altair OptiStruct: Topology Optimization with AM Constraints

If you need more control and advanced structural fidelity in your optimization, OptiStruct is Altair’s flagship solver.

- Supports topology optimization with AM-specific constraints (symmetry, minimum member size, draw direction).

- Allows multi-loadcase optimization, including vibration, thermal, and fatigue-driven design.

- Results can be directly exported to Inspire or meshed for AM printing workflows.

Fig 3: Optimized metal part 3D printed

Q6: Is Altair software suitable for startups or smaller teams?

A: Yes! One of the biggest challenges for Startup or smaller teams is the cost of engineering simulation tools. Altair offers startup acceleration programs and flexible licensing models that are designed to scale with your business. Small teams benefit from:

- The Altair One cloud platform for easy deployment and minimal IT overhead

- Shared unit pools across users, since many of them are required to wear multiple hats.

- Access to the full portfolio (simulation, AI, HPC, analytics)

Q7: How can I try the software? Is there a free trial?

A: Yes! Most Altair simulation tools offer free trials through the TrueInsight team. Along with the trial, TrueInsight offers personalized onboarding if needed and application-specific guidance.

Altair also offers no-cost, self-paced training and tutorials so users can ensure they are using the software correctly while evaluating it for their application.

Q8: Does Altair offer any AI-powered features?

A: Definitely. Altair is a leader in combining simulation with AI and machine learning. A previous blog post covered the AI tools in more depth as well. Key AI capabilities include:

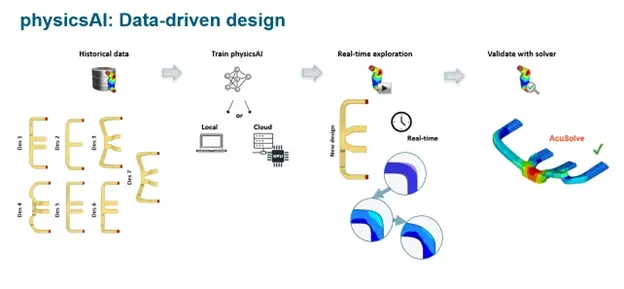

PhysicsAI is one of the most advanced and unique AI features in Altair’s simulation suite.

- Trains an AI model based on your existing simulation data

- Predicts results for new design variants in near real-time without solving the physics equations

- Works with structural, thermal, and fluid simulations

Fig 4: PhysicsAI workflow

RomAI supports the creation of AI-based surrogate models, lightweight models trained on detailed simulation data that:

- Provide quick feedback on performance metrics

- Integrate into real-time applications like digital twins or control systems

- Replace heavy, high-fidelity solvers in iterative design

These tools dramatically reduce simulation times and help engineers predict behavior faster.

These were answers to some of the most common questions we get asked as an Altair Channel Partner. If you have any other questions or want to learn more, let us know.