How SimSolid Accelerates Large Assembly Analysis Without Geometry Simplification

In this post we talk about how Altair SimSolid is ideal for simulation users working on large assemblies.

One common obstacle that many engineers face when working with large and complex CAD files is preparing these files for analysis. The endless cycle of geometry simplification, mesh cleanup, and computational bottlenecks has been the norm for decades. This is where Altair SimSolid can ease this pressure for its users. While SimSolid can handle complex physics scenarios like Linear and Nonlinear studies, Thermal analysis and Fatigue testing, it’s ideal for running these analyses in the design phase of the product development process. It allows users to help ensure they have a more qualified design before sending it onto final analysis, which can sometimes be a bottleneck.

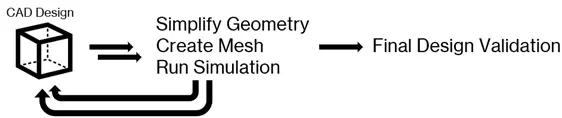

Fig 1: Traditional simulation process for large assembly

In this post, I’ll look at why geometry simplification is such a pain point, how SimSolid differs from the traditional FEA process, and what kind of results real-world companies are achieving by using it for large assembly analysis.

The Traditional Problem: Why Large Assemblies Are So Hard to Simulate

In traditional FEA workflows, the first step after importing CAD is usually geometry preparation. Engineers remove fillets, small holes, cosmetic details, and other features that aren’t “structurally significant”. Without this simplification, the solver will spend added time trying to capture irrelevant details, which can lead to large mesh sizes, failed runs, and painfully long solve times.

For small models, this cleanup process can take hours. For large assemblies, like automotive frames, heavy equipment, or consumer product assemblies, it can take more than a week. The time-consuming tasks lead to problems that can compound on each other:

- Meshing Instability: Meshing complex CAD with thousands of parts often leads to poor-quality elements or solver crashes.

- Assembly Connections: Defining accurate contacts, welds, and fasteners between hundreds or thousands of parts adds another layer of complexity.

- Solver Run Times: Even if you get a clean mesh, running a large-scale assembly simulation on a desktop workstation can take hours or even days.

What ends up happening, in many cases, is engineers either oversimplify their models (risking inaccurate results) or spend far too much time preparing geometry that doesn’t add real value to the project.

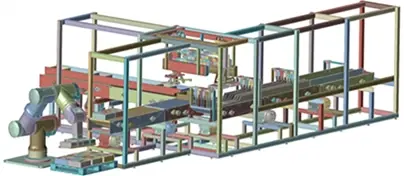

Fig 2: Example of large assembly model

Altair SimSolid: No Geometry Simplification Required

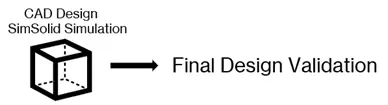

Altair SimSolid takes a different approach. Instead of relying on meshing, SimSolid uses meshless computational methods based on external approximation theory and multi-pass adaptive analysis to work directly on the original 3D CAD geometry, even if it’s very large or detailed. In simple terms:

- You can analyze CAD directly, even if it contains thousands of parts, bolts, or detailed geometry.

- There’s no need for simplification of small features, fillets, or holes unless you want to remove them.

- The solver automatically handles contacts, welds, and part connections with minimal manual setup.

This approach allows SimSolid to deliver:

- 10x–100x faster solve times compared to traditional FEA.

- The ability to run massive assemblies with thousands of components on a standard laptop.

- Results that are validated and benchmarked against classical FEA for accuracy.

In real-world applications, this means engineers can simulate models they would never attempt in traditional tools.

Fig 3: Shortened SimSolid validation process

Example: Automotive Assembly Validation

Consider an automotive body-in-white (BIW) analysis. This is the stage where a vehicle's body shell is assembled from its sheet metal components, but before it's painted or fitted with the engine, chassis, interior trim, or other parts. Traditional FEA would require weeks of cleanup and simplification to reduce the CAD to a solver-friendly state. Every spot weld and joint needs to be defined, every hole and fillet considered.

With SimSolid:

- The entire CAD assembly is imported directly, thousands of parts intact.

- Welds, connectors and fasteners are defined in bulk using SimSolid automation tools.

- A global stiffness and modal analysis can be completed within hours, not weeks.

The engineering team can then iterate on design changes quickly, evaluating stiffness, weight reduction, or crashworthiness in days instead of months.

Fig 4: Body in White example

Overall Benefits of Large Assembly Analysis in SimSolid

To summarize some of the main reasons why designers and engineers are incorporating SimSolid into their process:

-

Speed With Accuracy

Because SimSolid performs simulation on native CAD files, it eliminates hours, or even weeks of geometry prep. Instead of waiting for days for results, engineers can iterate in minutes or hours. This speed doesn’t come at the cost of accuracy; results are benchmarked against industry standards and NAFEMS.

-

Keep Design Integrity

When you simplify geometry, you risk losing design integrity. As we are all subject to human error, that tiny gusset or bracket you removed might actually play a critical structural role. By skipping simplification, SimSolid ensures that every feature is considered, improving confidence in your results.

-

Scalability for Large Assemblies

Whether it’s an aircraft cabin, a tractor chassis, or a consumer electronics product with hundreds of screws and fasteners, SimSolid scales effortlessly. Traditional FEA tools often begin to lose performance when such complexity is introduced, because the more nodes and elements that are created, the more processing is required. With SimSolid, it skips the meshing step and moves straight into your study setup.

-

Fewer Specialized Skills Required

Traditional meshing on complex assemblies typically requires highly trained analysts who know how to manipulate geometry for simulation. With SimSolid, design engineers and non-specialists can perform meaningful structural analysis earlier in the product development cycle. This allows designers to have a better understanding of how their design will perform before sending it to analysts, hopefully reducing the cycles of rework that can occur in this stage.

Large assembly analysis has traditionally been a big pain for simulation users for many years. Designers have either entered a loop of sending untested designs to their simulation teams, then getting the results and making design changes; Or spent a lot of time simplifying their geometry and creating a clean mesh, only to have their solve times be extended and really slowing down their development process.

Altair SimSolid can change this frustrating process. By eliminating the need for geometry simplification and meshing, it enables designers to run large-scale structural analyses directly on CAD assemblies, quickly, accurately, and on standard hardware before sending forward for advanced analysis.

If you have any questions or want to discuss Altair SimSolid further, feel free to reach out to us.