How Simulation Is Aiding Aerospace Design

Check out how simulation is being used in the space and aerospace industries to advanced their design processes.

The global aerospace and space industry is undergoing a major shift: commercial launches, reusable vehicles, small-sat constellations, eVTOL air mobility, hybrid propulsion and on-orbit servicing are all moving from concept into reality. For engineers and companies competing in this area, a few top priorities will continue to lead the way: Reducing risk, accelerating certification, optimizing for weight, reliability and performance.

In this post we’ll look at this shift and then show how the simulation suite from Altair Engineering aids engineers’ ability to handle the challenges of aerospace and space engineering.

Changes in the Industry

New market entrants and accelerated timelines

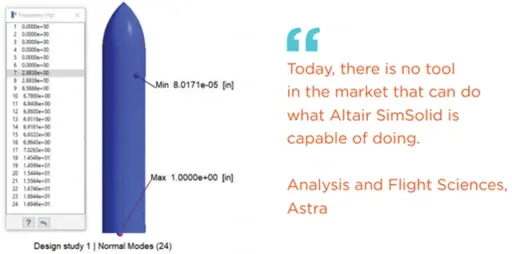

Space used to be the domain of large OEMs and governments, but now private firms (launch, satellite, servicing) are moving fast. These companies cannot afford long physical test cycles. Simulation enables faster iteration, earlier design exploration and lower risk. One such firm, Astra Aerospace, uses Altair SimSolid to speed up their design builds of launch vehicles by 10X over their previous methods, while maintaining accuracy.

Fig 1: Representative Model Rocket in Altair SimSolid

This ability to speed up development has also made companies who provide engineering services to the industry much more effective. TrueInsight customer, 3DB Engineering recently presented the Altair Simulate at the Speed of Design event and walked through how they are using Altair solutions to provide additional value to their aerospace customers. See the video at the bottom of this post.

Lightweighting and Multi-Physics Complexity

Every gram counts in launch and orbit. Structural, thermal, fluid, vibration, electromagnetics and system-level interactions all matter. A typical subsystem must withstand launch loads, space thermal cycles, radiation, then operate reliably for years. That means engineers must simulate across domains early.

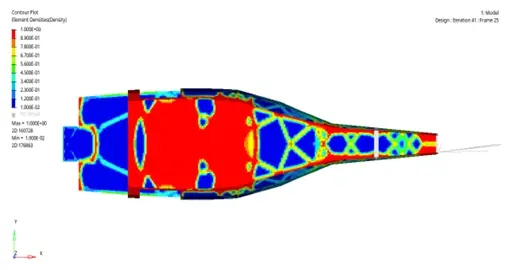

This is one of Altair’s greatest strengths, in that Altair OptiStruct includes one of the most powerful topology optimization solvers in the industry, that is widely used to reduce mass and volume.

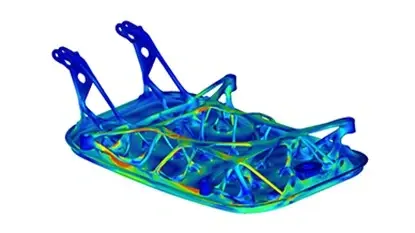

One example of a company using OptiStruct to enhance their processes in this way is SOGECLAIR Aerospace out of France. They use Altair HyperWorks (includes Altair HyperMesh and OptiStruct) to perform topology optimization and FE Analysis to reduce their development time and even integrate manufacturability simulation.

Fig 2: FEM results from access door from SOGECLAIR case study

Reusable and Next-Gen Platforms

Reusable rockets, space-plane concepts, urban air mobility (eVTOL) all bring additional constraints: fatigue, rapid turnaround, hybrid propulsion (electric/combustion), novel materials and manufacturing. These demand simulation workflows not just for static loads but for life cycle, systems modelling, real-time digital twins.

Altair created a great resource, Guide to Urban Air Mobility that walks through some of the challenges in this space like range and payload requirements, safety and regulation and infrastructure.

System-Level Simulation & Digital Twin

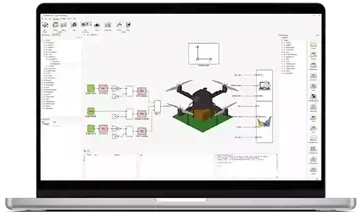

Modern aerospace platforms are typically more than just structures. They are integrated systems: Avionics, propulsions, control systems, thermal, structures, sensors, connectivity. Model-based systems engineering (MBSE) and simulation of system interactions are becoming mandatory. In this technical document, Altair walks through how these types of systems are being applied in aerospace design.

Fig 3: MBSE example in Altair Twin Activate

How Altair’s Simulation Platform Fits Aerospace & Space Engineering

Altair’s toolset is well-positioned to address these aerospace-space challenges through several key products and capabilities.

- Multiphysics & Systems Simulation

- Altair SimLab is the hub for process-driven multiphysics on complex assemblies with guided workflows for structural, thermal, electromagnetics, and fluids. It automates pre/post, keeps CAD associativity, and supports cloud runs. SimLab is ideal for aero-thermal-structural coupling on spacecraft, eVTOL, or payloads.

- For fluids, Altair CFD gives you multiple solvers under one license—finite-element Navier–Stokes (Altair AcuSolve), SPH (free-surface, sloshing), and LBM (aero & aero-acoustics), plus coupling for fluid structure interactions (FSI).

- High-fidelity Aerodynamics & Rapid CFD Studies

- Altair FlightStream uses a panel-method approach with viscous and compressibility effects, giving very fast aerodynamic turnaround for powered/unpowered configurations, which is great for early sizing of wings, propellers/rotors, fairings, and supersonic/hypersonic concepts before you get into advanced analysis that require more robust computing resources.

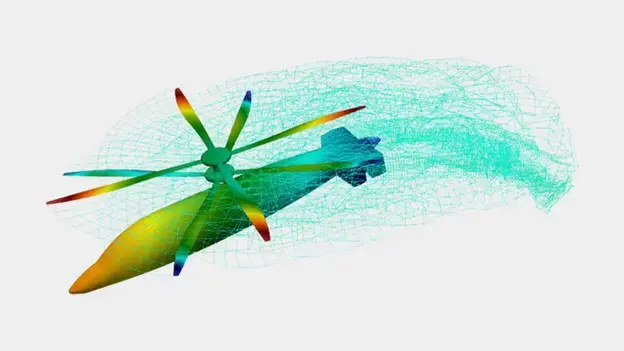

Fig 4: Rotorcraft aerodynamics simulation using Altair FlightStream

- Altair AcuSolve covers general-purpose RANS/transient multiphysics on unstructured meshes when you need higher fidelity, including aero-thermal and rotating machinery.

- Altair Flow Simulator (1D/3D system-level fluids/thermal) plugs the gap for propulsion/feed systems and environmental control loops. Use it to co-design system plumbing with your 3D aerodynamics.

- Structural FEA, Optimization & Lightweighting

- Altair OptiStruct includes linear/nonlinear structural analysis with a leading topology, shape, and sizing optimization solver stack. It’s widely used for aerospace lightweighting and durability.

Fig 5: Topology results on a helicopter fuselage

- Altair Inspire brings topology optimization and lattice generation to design engineers with manufacturing constraints. This can be useful for brackets, ribbing, and Additive Manufacturing ready geometries early in the process.

- System-Level Simulation & Digital Twins

- Altair Twin Activate models full vehicles as 1D multi-domain systems (mechanical, electrical, thermal) and is built to deploy real-time digital twins.

- Altair Compose is the math/scripting environment for CAE data processing, automation, model orchestration, and custom analytics. This is handy for requirements checks and batch pipelines.

- Altair Embed generates embedded code directly from control/system diagrams to supported MCUs (HIL-ready), closing the loop from model to flight/bench hardware.

- Resources for Aerospace Startups

- The Altair Aerospace Startup Acceleration Program (ASAP) is built for startups looking to break into the aerospace industry. Participants get full access to Altair Multiphysics, Data Analytics, Manufacturing Simulation, IoT and Digital Twin solutions and High-Performance Computing.

As the aerospace industry continues to evolve, the role of simulation will play a bigger part. If you have any questions or want to discuss any of these solutions mentioned in the post, don’t hesitate to contact us.