Looking at Different Methods of Optimization with Altair

In this post we look at some of the different methods of optimization that users can use within the Altair tools.

We are hearing the term “optimization” frequently when talking with end users about their design and engineering workflows. It’s a great sign that the technology fueling these processes is growing and giving users the ability to create better designs. In this post we will talk about some of the different methods of optimization in the Altair Engineering simulation suite and then talk about some of the best practices.

What Is Optimization?

At its core, optimization is a systematic way of refining a design to meet a specific objective like minimizing weight or maximizing stiffness, while respecting constraints such as material strength, manufacturability, or displacement limits. Including optimization in your process can lead to big benefits like: Cost and material savings, performance gains and design flexibility.

Altair is well-known as a leader in the optimization space and although we are going to highlight five of the methods of optimization in this post, there are many others that Altair offers and you can see more about those here.

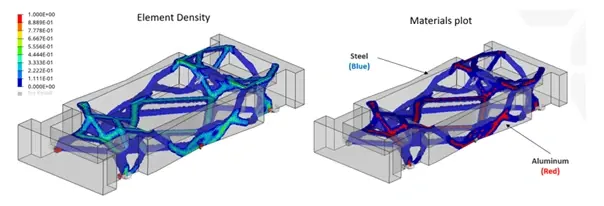

Topology Optimization

Topology optimization is a broad umbrella term that can be seen as more of a concept than the actual method. The basic idea is simple: You tell the software where a part could be or what the boundaries are, you also define loads and support points. Then, the software figures out which areas are most critical to reach the design intent. Think of topology optimization as digital carving, it progressively removes unnecessary material from a defined design space until only the essential load-bearing geometry remains.

The result is often an organic, sometimes complex structure that’s lightweight yet strong. With Altair solutions you can use built-in tools to help take those organic structures, that would be difficult to manufacture with traditional methods and smooth them out to make the manufacturing process more feasible.

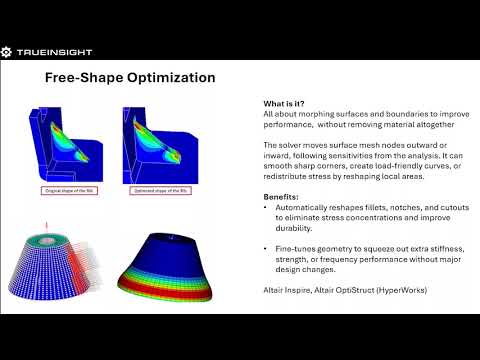

Fig 1: Multi-Material topology optimization example

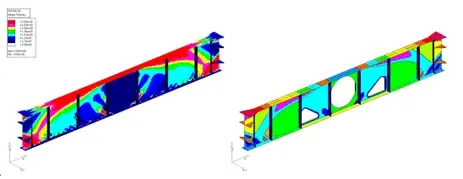

Free-Size Optimization

Think of free-size optimization as thickness tuning. Instead of removing material, it changes how thick or thin a part is in order to meet the defined objective. Shell analysis regions that aren’t as stress-critical get thinner, while load-bearing areas retain thickness.

This is very useful for parts made of thin sheets or composites where it helps decide how many layers to use and where. The most common applications for free-size optimization are scenarios like aerospace panels or automotive body structures where weight savings and stiffness are critical.

Fig 2: Free-Size optimization example

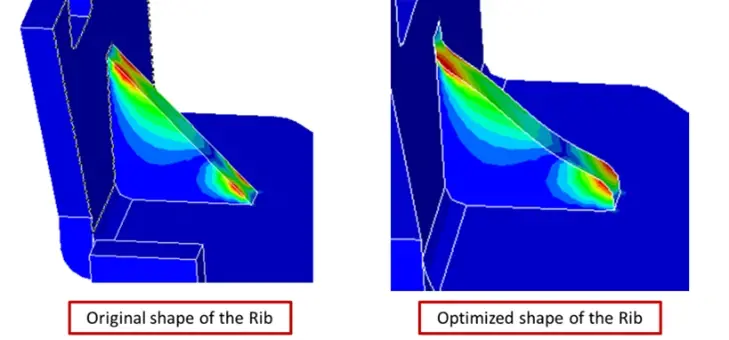

Free-Shape Optimization

This is one of the only methods that can change the shape of the design. Whereas other techniques take an established shape and optimize it, free-shape will move the surface nodes of a surface model to spread out applied loads more effectively. It’s often used in combination with topology optimization to refine a design into something more manufacturable.

It’s especially effective for scenarios that require reducing stress concentrations like fillets, notches or cutouts. Think of brackets, housings, or suspension components, anywhere you’ve got sharp corners or regions that could fail over time.

Fig 3: Rib design example using Free-Shape optimization

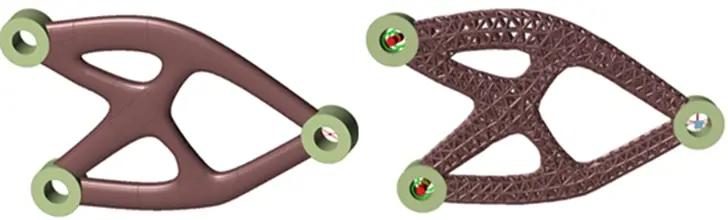

Lattice Optimization

Lattice optimization creates lightweight internal structures. Instead of having a solid block of material, the solver generates a network of struts or cells inside the part, kind of like the structure of bone or honeycomb. It also identifies regions where you can swap out solid material for a lattice pattern without losing performance by varying the density and orientation of the lattice depending on local loads. Lattices can also help with thermal management. More surface area typically means better heat transfer.

This method is best when you need both lightweight designs and good thermal performance. Applications like aerospace brackets, medical implants and consumer electronic designs benefit from adding this process to their workflow.

Fig 4: Before (left) and After (right) Lattice Optimization

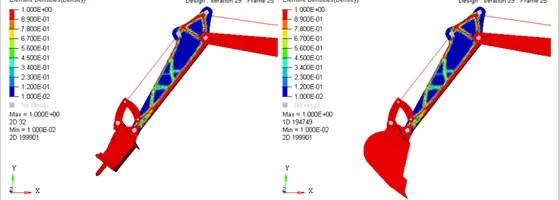

Multi-Model Optimization

Multi-model optimization (MMO) explores multiple linked design models simultaneously, seeking common design scenarios that perform well across them. Most designs don't just face one type of load in the real world.

Consider a suspension arm for an automotive design. Designers must account for bumps, braking, and temperature changes while in operation. Multi-model optimization lets you account for all those scenarios at once.

This prevents a common problem, where designs can be over-optimized for one load condition without considering other variables. MMO creates more robust designs and is critical for industries like aerospace and electronics.

Fig 5: MMO example showing stress flow under multiple loads

Best Practices for Optimization Projects

- Define clear objectives and constraints upfront. Whether that’s minimize mass, maximize stiffness, or hit specific frequency targets.

- Start with coarse meshes. Explore the solution space quickly, then refine for detail.

- Validate early. Run simple static simulations or stress checks before pushing into topology runs.

- Consider manufacturability. Don’t exceed manufacturable wall thickness, undercuts, or 3D printability constraints.

- Combine optimization phases: e.g., topology → topography → gauge → shape → final verification.

As mentioned before, Altair solutions offer many different techniques or methods of running optimization. Altair Inspire includes the ability to run topology, topography, lattice and manufacturing optimization techniques, amongst others. Altair SimLab offers thermal, multiphysics and CFD-driven optimizations. Lastly, Altair OptiStruct is the most complete optimization engine in the portfolio offering all of the aforementioned optimization types in addition to multi-material, frequency and fatigue-based optimizations.

Altair Inspire: Lightweight, designer-friendly, mostly topology/shape/size/gauge/lattice.

Altair SimLab: Analyst-oriented, multiphysics-driven (structural + thermal + CFD).

Altair OptiStruct: Full solver powerhouse with every optimization method, including advanced composite, free-size/free-shape, crash, fatigue, and multi-model.

To learn more about these methods and tools, or to talk deeper about your potential application, reach out to us.