Comparing Siemens NX to Dassault CATIA

Check out how Siemens NX compares to competitive tools in the industry in this post from TrueInsight

With Siemens recently acquiring Altair, the combination of these portfolios makes one of the most complete solutions in the market. One of those solutions that comes from the Siemens side of things is Siemens NX. Siemens NX, part of the Siemens Designcenter solution, is often described as a “do-it-all” mechanical design and manufacturing platform that scales from individual productivity to enterprise process control. It’s known for the wide array of capabilities it offers (part design, assemblies, surfacing, sheet metal, routing, drafting, CAM) plus a strong integration with simulation, manufacturing, and lifecycle management.

When organizations evaluate enterprise CAD platforms, Siemens NX is rarely considered in isolation. In this post we will talk about where Siemens NX strengths are compared to competitive tools in the space, mainly Dassault CATIA. Each platform has earned its place through decades of evolution, but they differ in a few areas that are worth highlighting.

Overall Platform

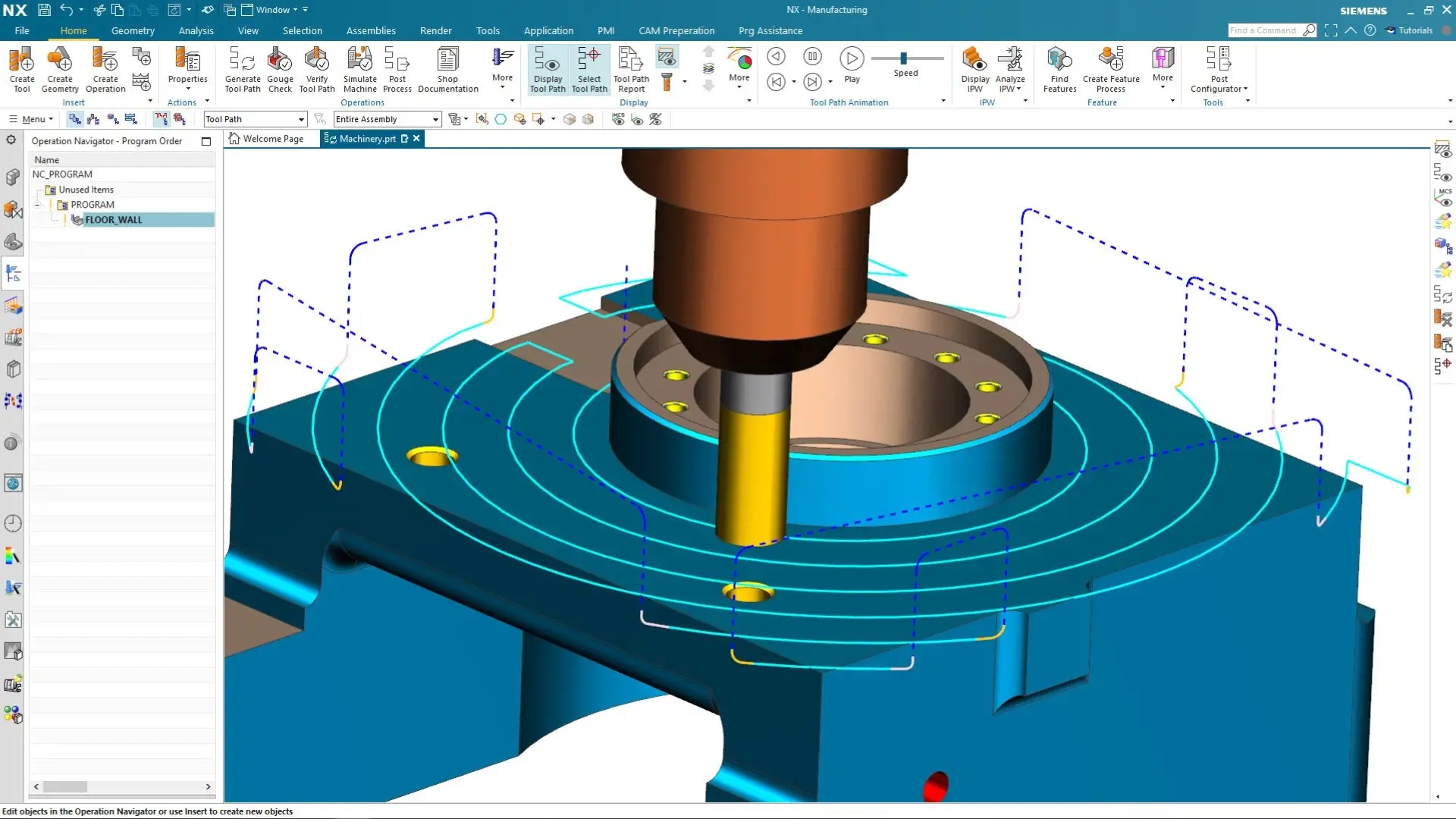

Siemens prides itself on providing a complete digital thread solution from concept through manufacturing. NX has a strong real-world advantage when organizations want to keep more of the workflow inside one environment, especially when you include NX CAM and the ability to move from design intent to manufacturing without translators, duplicate models, and error-prone handoffs. For teams doing high-mix machining, complex parts, and frequent iteration, time savings is a major reason users choose NX.

Fig 1: Siemens NX CAM

NX also works naturally with Siemens’ simulation portfolio. Models can be used directly with Siemens simulation tools such as Simcenter 3D, Simcenter STAR-CCM+, and Simcenter FLOEFD, allowing engineers to move from CAD to structural, thermal, and CFD analysis with minimal rework. Design changes made in NX reflect simulation models, supporting faster iteration and more confident decision-making earlier in the design cycle.

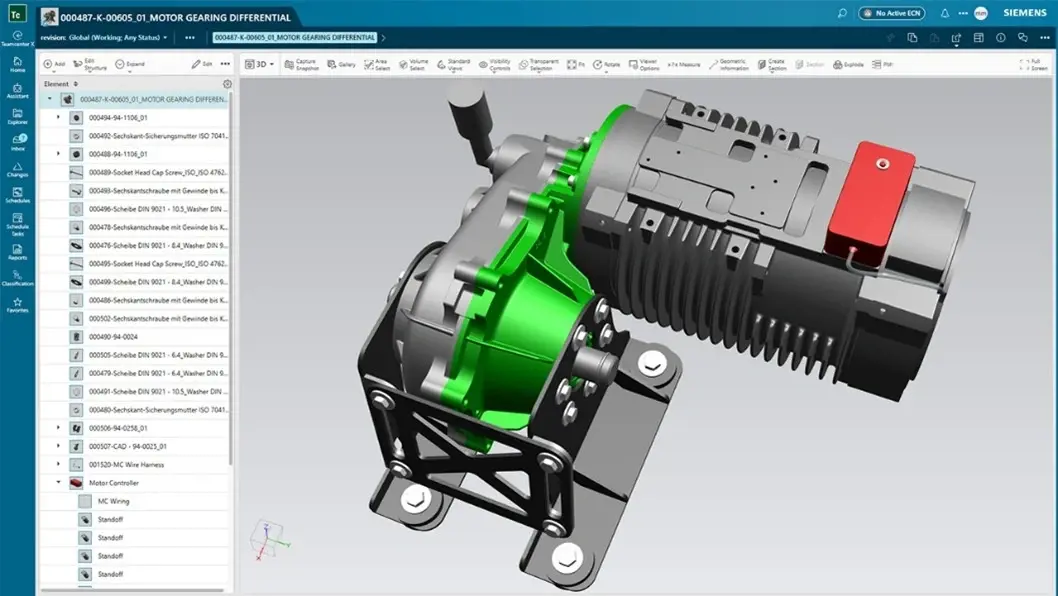

The Siemens portfolio includes a best-in-class product management solution, Siemens Teamcenter. NX users can check models in and out of Teamcenter directly, manage revisions and work with controlled product structures without leaving the design environment. Teamcenter also works well in a mixed CAD environment for managing multi-discipline BOMs and engineering change management, while users stay in their native CAD environments.

Fig 2: Siemens NX interface with Teamcenter integration

For CATIA’s platform, it connects to the Dassault 3DEXPERIENCE platform which is a role-driven, hosted environment for collaboration and workflow management. Everyday CAD actions like saving, revising, sharing or releasing data are governed by platform rules, which can be great for control, but can slow down processes. Simulation and CAM roles are also available with CATIA models being available through the platform, but similar to multi-CAD environments, workflows are governed by platform rules which can slow processes, especially when rapid iterations are needed.

Modeling Approaches and Capabilities

CATIA is traditionally based in a history-driven and feature-based modeling approach that works extremely well for large, highly controlled programs where geometry creation, dependencies, and configuration rules are carefully planned from the start.

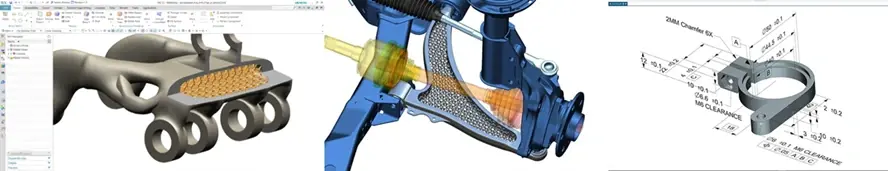

NX’s mix of history-based modeling and direct editing supports an important modern reality: engineers rarely work on pristine, fully parametric models all day. They work on imported data, legacy parts, supplier geometry, and late-stage ECOs where editing speed can matter more than feature-tree perfection. NX is frequently praised for being practical in day-to-day mechanical work: large assemblies, inter-part relationships, model management, and workflows that don’t demand specialized CAD expertise to be effective. In real-world application that matters, because we’ve seen with most engineering teams, the end result typically depends on the average user, not only the top performers.

Fig 3: Variety of modeling options in Siemens NX

Surfacing

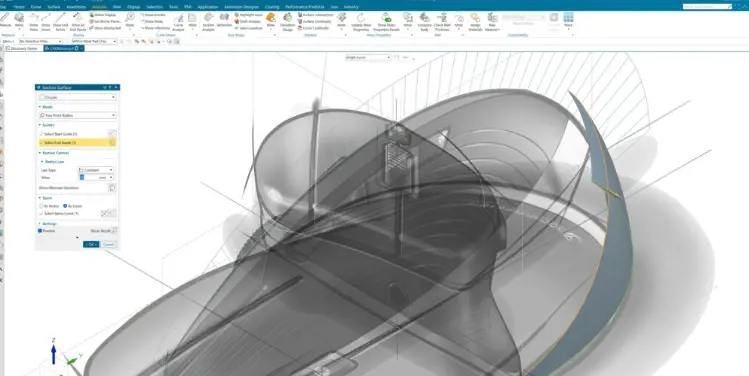

CATIA is commonly associated with workflows that require high-end surfacing like aerospace and automotive industries. NX also offers advanced freeform and Class-A–style surfacing tools such as studio surfaces, continuity controls, and curve-driven geometry as well. This means that teams that need advanced modeling capabilities can get that without sacrificing their practical day-to-day workflows.

Fig 4: Surfacing in Siemens NX

Training and the “Average User”

A platform typically excels when most of your team can produce correct models quickly and consistently. NX is frequently positioned as a strong balance of power and practicality. While still an advanced enterprise tool, is generally viewed as more approachable for a broader range of users. NX supports multiple modeling styles (parametric, direct, and hybrid) within a more unified interface, allowing engineers to be productive without mastering highly specialized workflows from day one. Users can start with straightforward mechanical design and gradually adopt more advanced capabilities as needed.

CATIA generally has a steeper learning curve, driven by its deep reliance on role-based functions, and process discipline, especially when deployed inside the 3DEXPERIENCE platform. Users often need to understand not only how to model geometry, but also how data is created, stored, configured, and released within the platform. This makes CATIA very powerful in tightly controlled environments, but it can slow onboarding and create dependence on highly trained “power users” or CAD specialists.

Overall

If your priority is a practical, scalable platform that excels in design-to-manufacturing workflows, supports flexible editing approaches, or one that aligns strongly with a Siemens-centric digital thread, Siemens NX frequently brings the clearest competitive advantages. If your world is complex shapes, aerospace program norms, or a Dassault-centered enterprise platform strategy, CATIA may be the natural fit.

And here’s the truth: both platforms are “good enough” on raw capability. The final decision is usually based on the one that best matches your ecosystem, manufacturing reality, and the day-to-day experience of your average designer, not just the power users.

If you want to learn more about Siemens NX or any of the solutions TrueInsight offers, let us know!