Using Decimation to Reduce the Mesh Size for Implicit Models in Altair Inspire

In this post we show how to use the decimation feature in Altair Inspire to reduce file size when working with STL files

With Altair Inspire, users are utilizing the impressive and powerful implicit modeling technology for lattice creation. Lattice files can be generated quickly and efficiently which can then be utilized for additive manufacturing by exporting mesh files such as STL, 3MF or OBJ files. One of the big challenges with printer slicing software is having a usable mesh file, specifically a file that is not a huge mesh size. This is why the modern 3MF or OBJ formats are advantageous vs STL, because they automatically compress file sizes. However, some slicers require STL format. In today’s blog I am going to run through how to use implicit mesh decimation to reduce mesh and file size!

Using Decimation

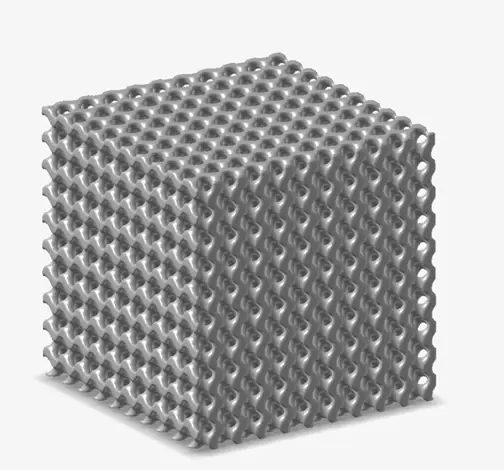

Let’s first generate a lattice in Altair Inspire. In this case, I am going to make a surface lattice on a cube and specify a gyroid lattice with a relatively fine density. For some reference on how to create a lattice in Inspire, check out the following video. The lattice we will create will be reasonably dense (Figure 1), so I can illustrate the decimate feature.

Figure 1: Gyroid Lattice of Cube

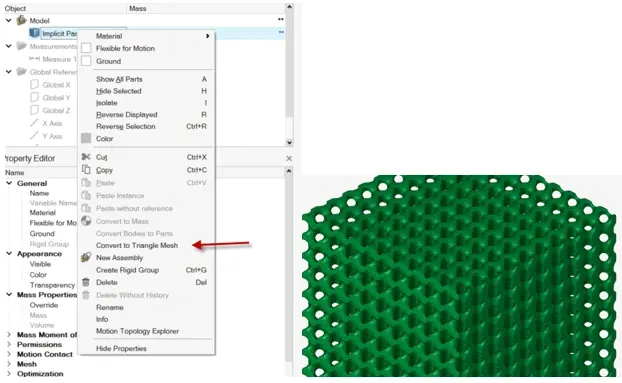

After a lattice is generated in Inspire, it can then be prepped to be sent to a 3D printer by saving out in a compatible printing format. In Inspire we can save implicit mesh files as STL, OBJ, and 3MF. For this, we will save out as STL, since those typically are larger file sizes. Prior to saving as STL, we can right click in our model tree and select convert to a triangle mesh (Figure 2). Inspire will ask you to specify the mesh size, but we will use the default third option which is applying a mesh based on the visualization quality. After the triangles are added, we can save the file out as STL to be printed.

Figure 2: Left Image: Location of Converting to Mesh Facets for Additive Export, Right Image: Mesh of Part

With the mesh generated, if I import it into my printing software slicer, I can see that for this particular file I have about 1.6 million mesh triangles, which gives an overall file size of 370 MB. However, with Inspire, I do have some options to reduce this file size, without having to change to a different format, this is where decimation comes into play!

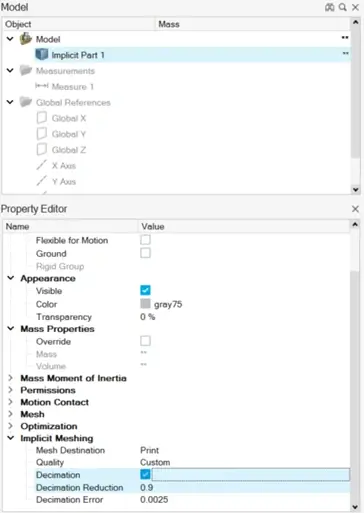

In Inspire there is an option called Implicit Mesh Decimation. Mesh Decimation is the process of simplifying a mesh by reducing the overall triangles of the mesh while preserving the original shape and geometric features of the mesh. The decimation setting can be set between 0 and 100 percent, where say for instance you put a value of .9, then Inspire will try and reduce the mesh elements by 90 percent. It is important to note there is also a Decimation Error option in Inspire, which means how much the new decimated mesh compares to the original mesh. So even if you specify a 90 percent reduction in elements, if the reduction violates the Decimation error tolerance (how much the new mesh compares to the original mesh), then it may not fully reduce elements by 90 percent.

The decimation size and decimation error can be set by clicking on the implicit part, and it is found in the Property Editor section under Implicit Meshing (Figure 3).

Figure 3: Location of Decimation Scale and Error for Implicit Parts

I decided to compare decimation options for three different sizes, non-decimated, 10 percent decimation and 90 percent decimation. The results of these are shown in the table below. We can see that to maintain a low , this means the new mesh must match the boundaries of the original mesh within the .0025 tolerance, that at 90 percent decimation its actually around a 50 percent reduction in file size. This is significant for those who need to use the STL format.

Model | Total Elements | File Size |

Non-Decimated Model | 1620672 | 370 MB |

10 Percent Decimated Model | 1458604 | 330 MB |

90 Percent Decimation | 814084 | 186 MB |

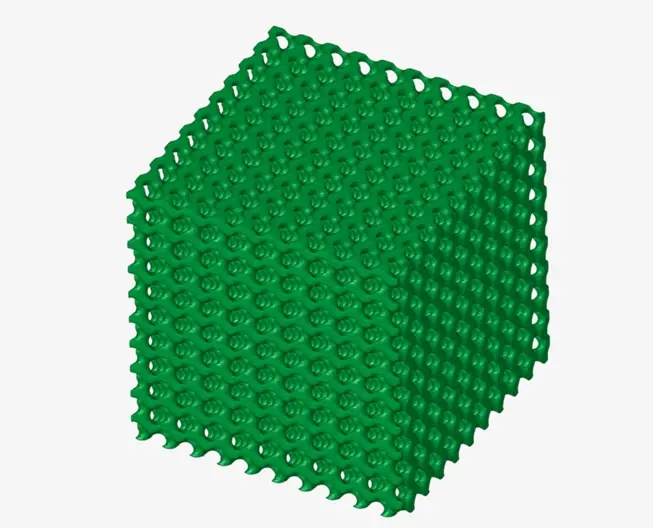

With decimation, I am still able to get an accurate final shape of my lattice, while reducing element and file size. It’s important to note, that if I had changed the decimation error, it would have reduced the elements further, but the shape to the original mesh would have differed. The final shape can be seen in Figure 4 below. We can see that with the .0025 decimation error, that our final shape matches very closely to our original mesh. I am happy with his shape, and happy with the size reduction, so we are now ready to print!

Figure 4: Final Decimated Shape of Mesh File

I hope this blog has illustrated how to reduce the file and element size of implicitly modeled parts using the decimation option! If you have any further questions on Altair Inspire or any other Altair solution, please reach out to us here at TrueInsight.