Getting Valuable Insights from Altair Inspire Cast

Altair Inspire Cast helps users understand any potential manufacturing defects in the metal casting process. This blog walks through one example.

Gravity casting is a widely used manufacturing process that involves pouring molten metal into a mold to create metal components. To ensure the quality, integrity, and cost-effectiveness of these components, manufacturers turn to simulation software. Altair Inspire Cast is one such powerful tool that enables engineers and designers to optimize the casting process. In this blog post, we'll explore some of the key results you can achieve by running a gravity casting simulation in Altair Inspire Cast.

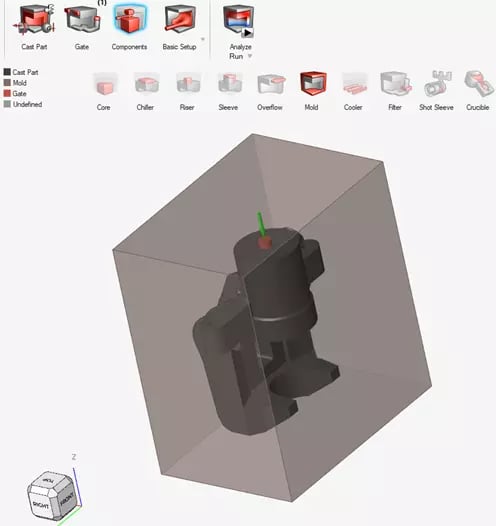

Before I run my analysis, I needed to define a few of the casting boundary elements. As seen in Fig 1. below, I added a gate on top of the part, and then created a mold component. You can see the different options in the ribbon menu that users can include other common components, like cores, risers and chillers.

Fig 1: Casting Components in Inspire Cast interface

Fig 1: Casting Components in Inspire Cast interface

Filling Results

With the filling results you are typically looking for potential defects that could arise during the process of the molten material filling your mold. So, depending on your results you can look at adjusting your gate placement, fill time, temperature or process parameters.

Let’s look at a few of the more common results here:

- Solid Fraction – It is a crucial parameter to monitor and understand because it directly impacts the quality and integrity of the final cast component. Essentially this shows areas that might be prone to not fill completely. If your model is solid red, that is a good thing. If you see some multicolored areas, you can adjust the pressure, velocity, or filling time.

- Mold Erosion – This shows you where velocity reaches a threshold where mold erosion can occur. This phenomenon occurs as the liquid metal flows through the gating system and into the mold cavity, which exerts pressure and thermal loads, causing abrasion against the mold walls. Mold erosion can lead to dimensional inaccuracies, surface defects, and even structural weaknesses in the final castings.

- Cold Shuts – This shows where two fronts of the molten material interact so there is potential for them not to fuse together properly. You can look at the temperature differences in the mold fronts to see if you need to adjust the filling process. This can weaken the structural integrity of the casting, making it more susceptible to defects, fractures, and premature failure.

Fig 2: Animation of cold shuts

Solidification Results

Running solidification simulations in metal casting can be helpful in optimizing processes, reducing defects, and achieving cost-effective, high-quality castings. With solidification you are typically looking at the cooling process rather than the filling process.

- Porosity – this refers to small voids or pockets of air that can be found in a finished part. With Inspire Cast this is a straightforward result that shows you the areas that are voids vs solids based on your specified percentage value. This result shows you the macro porosity or the shrinkage porosity.

- Niyama Criterion – Essentially this is a “safety check” for how well material is fused, so it helps you understand the potential for shrinkage and microporosities. When the Niyama value falls below a certain level then micro-shrinkage begins – the lower the value, the higher the probability of micro-shrinkage porosity.

- Pipe Shrinkage – This is characterized by the formation of a cavity or void at the center of the casting, typically near the top or innermost part of the component. It is commonly associated with a cooling process where the surface is exposed to the environment.

Fig 3: Animation of Niyama Criterion results

Inspire Cast helps predict and prevent casting defects such as shrinkage porosity, cold shuts, and non-fills, while also offering insights into optimizing mold designs, gating systems, and material selections.

By simulating and visualizing the casting process, Inspire Cast empowers users to make informed decisions, resulting in cost savings, improved casting quality, and enhanced overall efficiency in metal casting operations.

If you have any questions on Altair Inspire Cast or any of the manufacturing solutions from Altair, don’t hesitate to contact us.