Getting to know Siemens Simcenter FloEFD

Siemens FloEFD is a CAD-Embedded CFD solution that is powerful for many applications. See why users choose it.

Siemens Simcenter FloEFD is a CAD-embedded CFD tool built to help engineers analyze fluid flow and heat transfer without leaving their design environment. Instead of exporting geometry, rebuilding setups, and handing models off to a dedicated analyst, users can define materials, apply power loads, simulate airflow, and evaluate temperatures directly inside their CAD workflow. In this post, we’ll walk through why engineers and companies tend to choose FloEFD as their solution. We’ll look at the features that make it approachable, the types of problems it’s particularly good at solving, and the practical reasons teams adopt it over other CFD tools.

CAD-embedded means fewer handoffs and less geometry pain

FloEFD being embedded in CAD is one of its biggest advantages. When the simulation environment understands the CAD model and its structure, you get a more direct pipeline from design intent to analysis intent. FloEFD often wins on time-to-first-answer and the ability to keep analysis synchronized with design.

Typically, one of the most time-consuming steps in the CFD process is everything before the solve:

- Simplifying geometry

- Fixing tiny gaps and overlaps

- Defining volumes

- Exporting/importing

- Rebuilding boundary conditions after every revision

Fig1: Flow trajectories from within Siemens NX interface

A workflow that’s more approachable for non-CFD specialists

A lot of organizations don’t have the luxury of a CFD expert on every project. They have mechanical engineers, electronics engineers, and product designers who need thermal and flow guidance without becoming full-time CFD specialists.

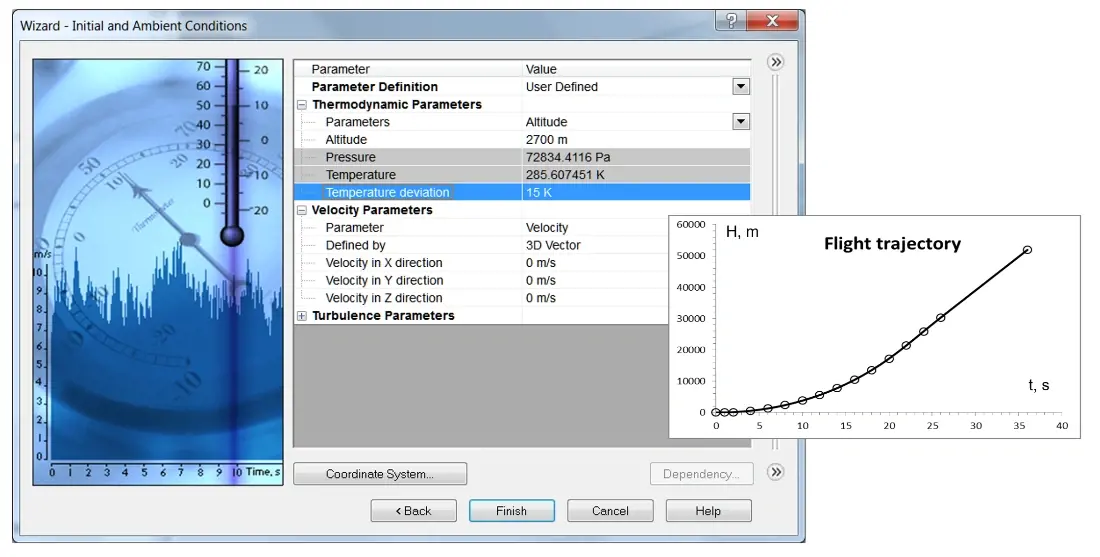

FloEFD’ s workflow tends to be more structured and guided than many traditional CFD packages. Users benefit from a tool that lead them through the process in a consistent order. The setup process is guided and consistent:

- Boundary condition setup is organized and repeatable.

- Users are prompted for key physics choices (internal/external, steady/transient, incompressible/compressible, etc.)

- Many common scenarios (electronics cooling, internal flows, external aerodynamics at design level) are straightforward to configure.

- It’s easier to standardize across a team (templates, repeatable study structure, design variants).

- You can build a checklist-like habit: define goals, apply materials, set fans/heat sources, solve, review.

This isn’t to say that users don’t need any CFD experience or education to get accurate results from FloEFD, but they also don’t need to be CFD specialists. The specialists can use FloEFD as well but might still also use Siemens STAR-CCM+ or another high-end solver for final validation.

Fig 2: Siemens FloEFD Wizard example

Strong fit for electronics cooling and thermal design problems

FloEFD is often chosen for electronics cooling because it maps well to the questions teams ask like:

- Where are my hot spots and recirculation zones?

- Do I need a bigger heat sink, better TIM (Thermal Interface Material), or better airflow path?

- What happens if I change the vent pattern or rotate the fan?

- How sensitive is this design to ambient temperature?

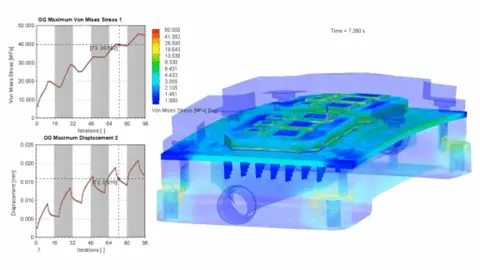

Thermal problems can be especially painful to “guess” your way through. Small geometry changes can have big impacts on airflow and heat transfer. FloEFD has features designed to get accurate answers:

- Conjugate Heat Transfer. Solving conduction in solids and convection in fluids simultaneously. FloEFD solves this in one coupled model without needing separate setups for solid and fluid domains.

- Native Handling of Electronics Heat Source. FloEFD allows users to apply volumetric heat sources, surface heat loads and component-based power inputs.

- Built-in Radiation Modeling. This includes surface-to-surface radiation modeling, gray-body radiation assumptions and configurable emissivity properties.

- No manual h-Coefficient Guessing. FloEFD solves fluid flow and temperature change together.

- Fan and Blow Curve Integration. Instead of assuming a fixed flow rate, FloEFD solves where the fan operates based on system resistance.

If you’re doing enclosures, power electronics, battery packs, consumer devices, industrial controls, or any product where thermal risk drives design, FloEFD can pay for itself just by helping you avoid a late-stage redesign.

Fig 3: Thermal example using FloEFD 2506

Reliable meshing and automation that reduce user error

As with most simulation studies, with CFD, accurate end results depends on the accurate setup. However, CFD setup can be fragile: Wrong boundary condition, poor mesh near a heat source, bad domain sizing and unnoticed leakage gap are all things that must be considered when setting up accurate analyses.

FloEFD is popular because it tends to provide:

- Automatically resolves near-wall regions to balance accuracy, solve time and stability.

- Geometry-adaptive mesh refinement during solve to improve resolution dynamically.

- FloEFD primarily uses a Cartesian (rectangular cell-based) mesh structure. It overlays a structured grid onto the domain and automatically resolves geometry intersections.

- Mesh structure aligns across solid-fluid interfaces to avoid common discretization mismatches.

Fig 4: Cartesian meshing example in FloEFD

Integration with Siemens workflows (NX, Teamcenter, Simcenter ecosystem)

Siemens prides itself on offering a complete digital thread within its ecosystem. If your company is already standardized on Siemens tools (or considering moving to Siemens tools), FloEFD’s integration can be a major advantage:

- Common environment and data continuity.

- Easier management of revisions and design updates.

- Potential alignment with broader simulation and PLM practices.

This matters because tool adoption isn’t just about solver capability, it’s about organizational adoption. When the CFD tool fits into your existing CAD/PLM workflows, it tends to get used more consistently.

When to consider Siemens Simcenter Star-CCM+

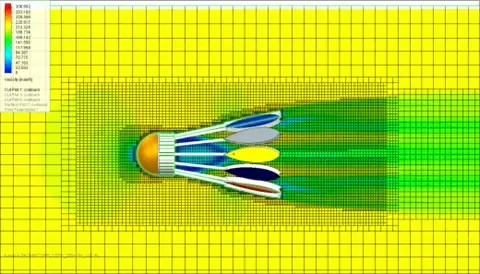

While FloEFD is powerful for many applications, Siemens also offers Star-CCM+, which is a very powerful, advanced CFD platform. Tools like STAR-CCM+ can be a better fit depending on the physics, the required validation rigor, and how specialized your team is:

- Highly specialized turbulence modeling (Large Eddy Simulation (LES), Detached Eddy Simulation (DES) or Hybrid models).

- Extreme multiphysics coupling beyond typical design-stage needs.

- Very advanced meshing strategies and manual control for complex physics like rotating machinery or turbomachinery.

- Multiphase flow studies require Volume of Fluid (VOF) or surface tension physics.

Fig 5: Siemens Simcenter Star-CCM+ examples

In a real-world application, the “best” CFD tool is the one your team will actually run often enough to change outcomes. FloEFD gets selected in most cases because it lowers friction, less prep, fewer handoffs, faster iteration, and tighter CAD integration. For many product teams, that means more simulations earlier, fewer thermal surprises later, and better decisions made when change is still cheap. To discuss FloEFD further feel free to reach out to us.