Differentiating Altair PollEx and PollEx for ECAD

Looking to understand the capabilities of Altair PollEx for Electronic Design Automation? Look no further. This post explains the tool.

In the last two years, we have seen a trend of more customers interested in Altair PollEx for printed circuit board (PCB) design and verification and circuit simulation. Specifically, the conversations generally center around what problems can PollEx help them solve that are typically not included within their PCB Design tool. In this post, I want to talk about the difference between the PollEx for ECAD extension, and the full PollEx simulation tool.

With both versions of the tool, the biggest benefit customers see is the ability to detect design defects, up to 900+ potential defects, early in the design cycle, which saves a lot of time and headache for end users.

The PollEx for ECAD extension is currently available for Altium Designer users (with additional PCB design tool integration coming soon). The extension allows users to perform additional simulation tasks, at no cost, from within the Altium design environment. The full PollEx suite is a stand-alone tool, that can work within existing workflows regardless of your PCB design tool, which includes Cadence, Eagle, Mentor Graphics, Altium and Zuken.

The easiest way to talk about the differences in these packages is to break it down into a couple categories: Solver Access and Verification Tools.

Solver Access

Signal Integrity

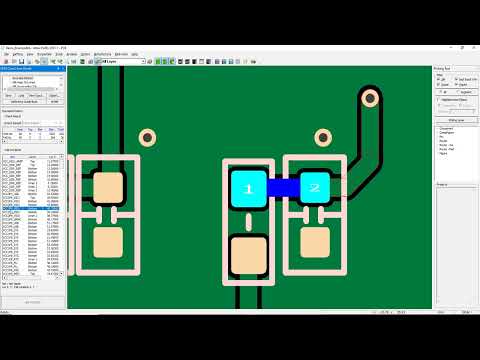

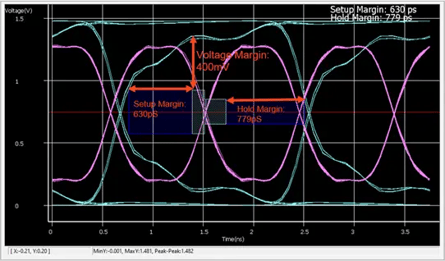

ECAD Extension: The ECAD Extension does include access to some powerful signal integrity simulation tools including Time and Frequency Domain Analysis, Eye Diagram, TDR, S Parameter Extraction and Post-Layout Topology Analysis.

Full PollEx: The full PollEx suite builds on top of that foundation to include Automatic DDRx Bus Analyzer, Crosstalk Analysis and Radiated Emissions Analysis. Figure 1 below shows the results of a DDR Design Case Study.

Figure 1: Signal Integrity Plot Crosstalk

Figure 1: Signal Integrity Plot Crosstalk

Power Integrity

Currently there is no power integrity tools built into the ECAD Extension, but there is some robust capabilities in the full PollEx version like DC IR Drop, PDN, SSN and Decap Analysis.

Thermal Analysis

ECAD Extension: There is access to some limited tools in the ECAD extension including defining the global conditions and defining forced and natural convections.

Full PollEx: In the full version, users can define convection coefficients, as well as execute local boundary conditions, molding, enclosure modeling and heatsink modeling. Figure 2 shows the visualization of a coupled thermal analysis between Altair PollEx and Altair SimLab.

Figure 2: Enclosure CFD utilizing PollEx and SimLab

Figure 2: Enclosure CFD utilizing PollEx and SimLab

Verification Tools

Moving onto the verification tools. There are a few things that are only available in the full PollEx version like Design for Assembly (DFA) tools, which covers the collision, lead and placement for assembly; AND Design for Electric + (DFE+). However, there are a few areas that each both the ECAD extension and full version of PollEx include rulesets: Design for Manufacturing (DFM) and Design for Electric Validation (DFE).

Design for Manufacturing (DFM). Starting with DFM, these tools help users understand aspects of their design related to the physical manufacturing of the PCB. These rulesets include verification for boards, components, FPCB, placement, drill size, pads, patterns and tooling.

The ECAD extension includes 52+ rules including:

- Board Spacing

- Solder Mask Violation

- Pin Arrangement

- Component Placement

- Drill size of hole, pin and via

- Keep Out Patterns

The full version of PollEx includes all the rulesets in the extension, plus some additional rules for increasing efficiencies for fabrication, mounting, assembly and end of line testing with more than 158 different rules that can be applied.

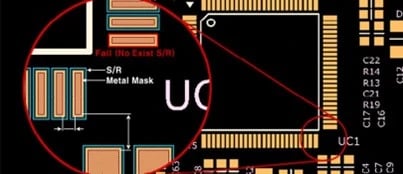

Figure 3: Example of Failed DFM analysis

Figure 3: Example of Failed DFM analysis

Design for Electric Validation (DFE). The licensing setup in this category is very similar to the DFM portion in that the ECAD extension offers some powerful capabilities, but the full version offers those capabilities plus much more. With DFE there are different classifications for the different rulesets such as: High Speed Signals, Differential Pairs, Board Rules, Net Rules, Power Rules and Component Rules.

The ECAD extension includes 36+ rules including:

- Complete Shield

- Copper Cross Over Detection

- Board to Net Clearance

- Antenna VIA

- Component Shield

The full version of PollEx includes 68+ rules allowing users to check for EMI vulnerability, ESD Protection, verifying return path routing.

Hopefully this has helped establish some of the differences between the two version of Altair PollEx to help you understand the value of each package.

One thing that always helps to understand how these tools can be used is looking at a customer case study. Samsung SDI was able to save $6M USD per year by incorporating the PollEx collaborative environment to ensure their distributed teams were working within the design rules at a global scale.

In addition to that, Altair has set up a resource to directly talk about PollEx Applications here.

Below are a few videos highlighting both the ECAD Extension and the Full PollEx license.

To learn more about Altair PollEx or any of the Electronic Design Automation (EDA) tools from Altair, contact your TrueInsight Account Manager or email inquiries to [email protected].