How the Altair and Siemens FEA Solvers Complement Each Other

In this post we look at the new combined portfolio from Altair and Siemens, specifically the FEA solvers

With Altair and Siemens now united, it's useful to examine how their simulation tools complement one another. Both address similar physics but differ in workflow, user profiles, and lifecycle stage. This post compares the core FEA tools from both portfolios: Altair SimSolid, OptiStruct, Radioss, SimLab, HyperMesh, Siemens Femap, and Siemens Nastran, summarizing their capabilities and best uses.

Structural Solvers

Altair SimSolid

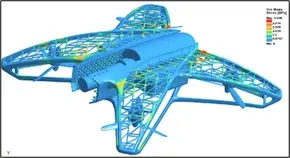

Altair SimSolid delivers fast, reliable results on CAD geometry without meshing, supporting key structural analyses. It is typically used early in design to optimize models for further analysis.

SimSolid’s solver technology is optimized to handle large and complex, real-world geometry (including gaps, overlaps, and mixed part sizes) without requiring geometry cleanup or defeaturing.

Fig 1: Drone design in Altair SimSolid

SimSolid excels in environments where speed and iteration frequency matter more than deep solver tuning. It enables engineers to run structural studies early and often, even while designs are still changing daily.

It is particularly well-suited for:

- Early-stage design validation

- Rapid “what-if” studies

- Large assemblies with many bolted or welded connections

- Teams that want simulation insight without FEA specialization

Altair OptiStruct

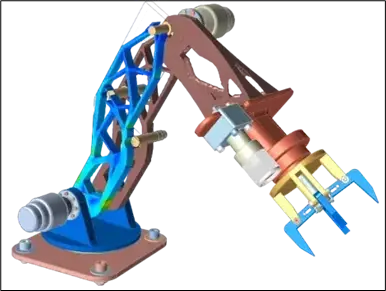

Altair OptiStruct is a high-performance implicit structural solver with a strong emphasis on optimization-driven design. OptiStruct is widely recognized for its advanced topology, size, shape, and free-size optimization capabilities.

While it is recognized for optimization, it’s also very strong in terms of day-to-day analyses, such as linear and nonlinear structural analysis, and is designed to handle large models efficiently, supporting multi-loadcase and multi-constraint design scenarios common in real production programs. OptiStruct is often positioned as the engine that helps teams arrive at better designs faster, rather than simply confirming whether an existing design passes.

Fig 2: Altair OptiStruct model with optimized arm

OptiStruct is ideal when simulation is being used not just to validate designs, but to actively improve them. It is most valuable when performance targets such as weight, stiffness, frequency, or durability must be balanced against competing constraints.

Common use cases include:

- Lightweighting and mass reduction programs

- Structural performance

- Concept-to-production optimization workflows

- Design exploration under multiple load cases

Altair Radioss

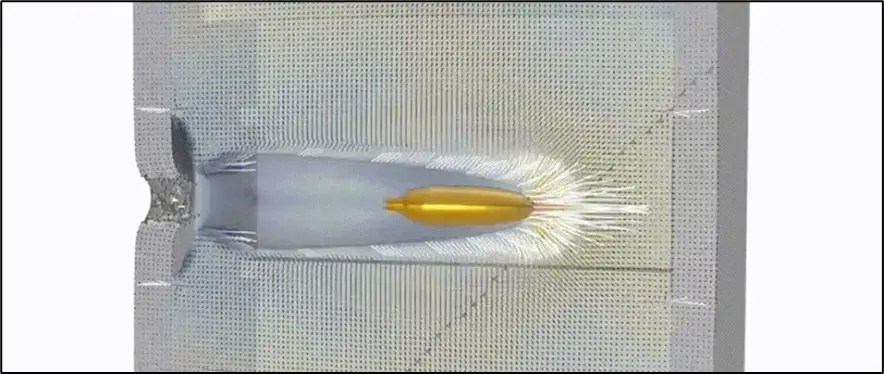

Altair Radioss is an explicit dynamics solver built to simulate highly nonlinear, transient events involving large deformations, complex contact, and short-duration loads. It is designed for problems where inertia effects dominate and where traditional implicit solvers struggle. Radioss typically complements implicit solvers by covering the class of problems where explicit time integration is required. Radioss also handles material nonlinearity, failure modeling, and contact-rich scenarios with high numerical stability.

Fig 3: Blast and ballistics example in Altair Radioss

For many Radioss has become a “go-to” tool for events that happen quickly and/or violently, where impact, crash, or drop behavior defines product performance.

It is particularly effective for:

- Impact and crash simulations

- Drop tests and safety events

- High-speed contact problems

- Progressive failure studies

Altair SimLab

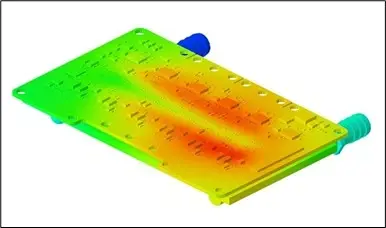

Altair SimLab is a simulation process and workflow platform that allows users to perform model preparation, solver execution, and post-processing across multiple physics domains (FEA, Electromagnetics, CFD). Rather than focusing on a single solver, SimLab emphasizes process automation, repeatability, and multiphysics workflows. It supports template-based modeling, parametric studies, and consistent analysis execution across design variants. SimLab often acts as the “glue” that connects solvers, geometry, and business processes into a repeatable digital thread.

Fig 4: Electronics cooling example in Altair SimLab

SimLab is best suited for organizations that want to scale simulation across more users and designs without increasing analyst workload in proportion. This works well because the learning curve associated with many analyst-level tools can be a significant obstacle for companies that want to incorporate more analysis into their workflow.

Key use cases include:

- Standardized simulation templates

- Automated design studies

- Multiphysics workflows

- Reducing dependency on solver experts

Siemens Simcenter Nastran

Siemens Simcenter Nastran is a general-purpose structural solver with a long history in aerospace, defense, and industrial applications. It supports a wide range of linear and nonlinear analyses, including statics, dynamics, buckling, and frequency response.

Nastran is known for its robustness, solver transparency, and widespread acceptance across regulated industries and remains a cornerstone solver in organizations where structural simulation must be auditable, repeatable, and widely trusted.

Fig 5: Turbine example in Siemens Simcenter Nastran

Nastran is most effective in environments where solver pedigree, consistency, and organizational standards are critical.

Typical use cases include:

- Certification and compliance-driven analysis

- Mature analysis workflows with legacy models

- Long-term programs with strict validation requirements

- Supplier and partner model exchange

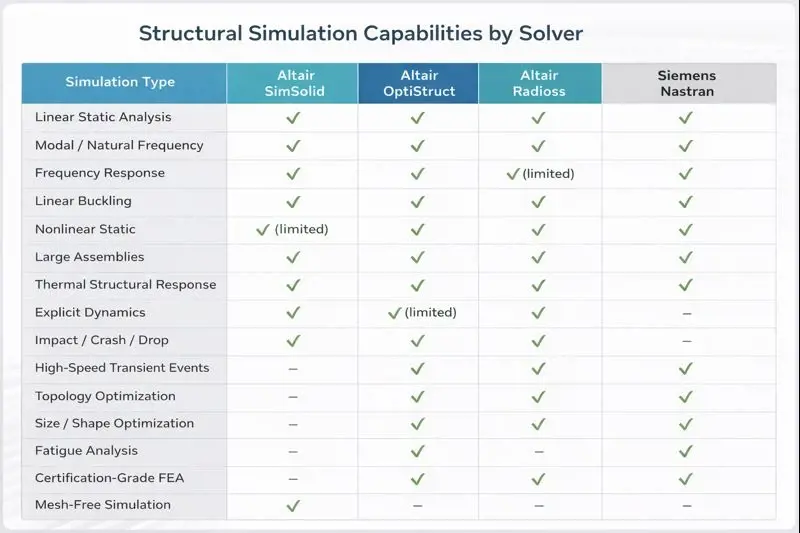

Fig 6: Table comparison of structural solvers and their simulation types

Pre and Post Processing

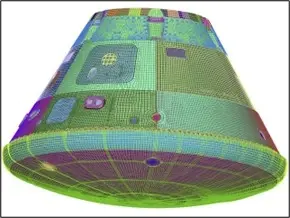

Siemens Simcenter Femap

Siemens Simcenter Femap is a powerful pre- and post-processing environment used primarily with Nastran-based workflows. It provides extensive tools for geometry idealization, meshing, model setup, and results visualization. Femap is solver-agnostic by design but is most commonly deployed alongside Siemens Nastran.

Fig 7: Meshing example is Siemens Simcenter Femap

Femap is well-suited for experienced analysis teams that require fine control over model construction and interpretation.

Common use cases include:

- Complex mesh control and refinement

- Large structural model management

- Detailed results interrogation

- Long-lived structural analysis programs

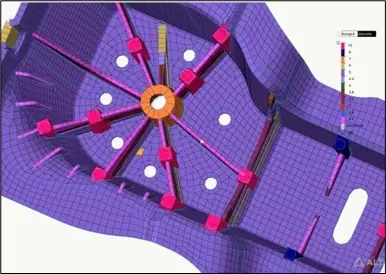

Altair HyperMesh

Altair HyperMesh is an industry-standard finite element pre-processing and model-building environment designed for creating, editing, and managing complex simulation models at scale. It provides advanced geometry cleanup, midsurfacing, meshing, assembly management, and model validation tools, with strong support for large, detailed models and multiple solver formats. HyperMesh is solver-agnostic and widely used to prepare models for OptiStruct, Radioss, Nastran, and other industry solvers.

Fig 8: Meshing and subsystems example in Altair HyperMesh

HyperMesh is best suited for teams that require maximum control over model fidelity and mesh quality, especially for large or highly detailed assemblies. It is commonly used when simulation accuracy depends heavily on careful idealization, element selection, and mesh refinement, and when models must be reused, updated, or extended across long product programs.

- Typical use cases include:

- High-quality mesh generation for complex geometry

- Large assembly model management

- Solver-specific model preparation and validation

- Structural, crash, and durability workflows requiring detailed control

At a high level, these solvers aren’t trying to do the exact same job. They’re designed to work at different speeds, depths, and moments in the engineering process. Tools like SimSolid make it easy to get quick structural insight early. OptiStruct takes things further by helping teams optimize performance and weight while providing accurate simulation results. Radioss handles tough impact and crash-style events, and Nastran provides the trusted backbone for detailed, signoff-level structural analysis.

If you want to learn more about the entire solution or any specific applications, don’t hesitate to let us know.