Migrating from Altair FluxMotor to Flux: Streamlining Motor Design and Analysis

In this post we look at Altair Flux and specifically Altair FluxMotor for motor design and analysis

Altair FluxMotor and Altair Flux are both impressive tools in the Altair suite of electrical and mechanical engineering. These tools excel in the simulation and optimization of low-frequency electromagnetic devices. Specifically, Altair FluxMotor is a two-dimensional “template-based” or “menu-based” approach to designing and analyzing rotating machines, and it includes the ability to perform open-circuit characterization, thermal analysis, working point analysis, and other simulations; Altair Flux is a more open-ended tool, allowing users to design any low-frequency electromagnetic device (including rotating machines or other devices, such as transformers) in 2D, 3D, or quasi-3D, and this tool also includes an even wider range of simulation results available for calculation.

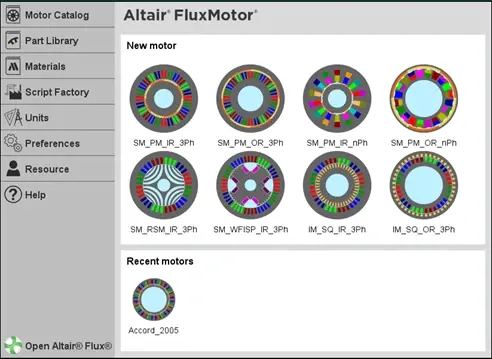

Today, we will be looking at how engineers can actually use these tools in tandem to expedite the design of their rotating machines. For this process to work with the current version of Altair FluxMotor, we must work with one of the following types of machines:

- 3-Phase Permanent Magnet Synchronous Machine (Inner or Outer Rotor)

- n-Phase Permanent Magnet Synchronous Machine (Inner or Outer Rotor)

- 3-phase Reluctance Synchronous Machine (Inner Rotor)

- 3-phase Wound-Field Inner Salient Pole Synchronous Machine (Inner Rotor)

- 3-phase Squirrel-Cage Induction Machine (Inner or Outer Rotor)

Fig 1. Introductory view of Altair FluxMotor.

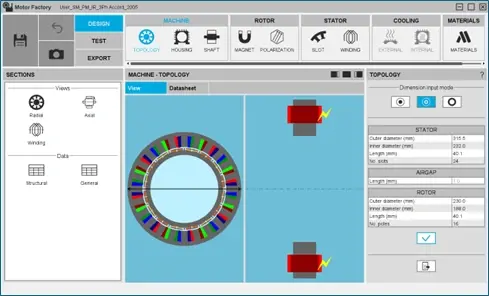

If we have one of the machines listed above, we are ready to move forward! We can simply use the formulaic approach of Altair FluxMotor to design our machine. Since we are focused on the connection with Altair Flux, we will save the discussion on these specifics for another day. Figure 2 below shows how we can select each element of our machine, choose high level options, and define unique characteristics to model our motor.

Fig 2. Motor Design in Altair FluxMotor.

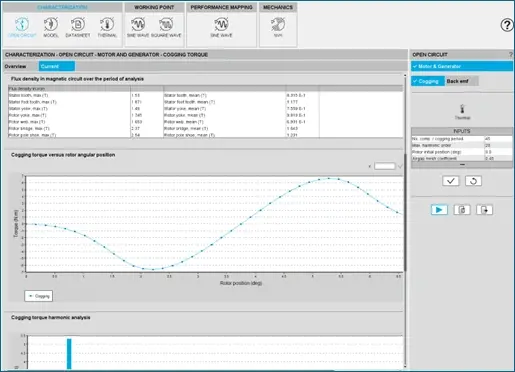

Once we are satisfied with the definitions of our motor topology, rotor, stator, and other physical and material parameters, we can move along to the testing or simulation stage of Altair FluxMotor. Figure 3 below shows all the different types of tests available to users in this stage of the process. Additionally, you can see some initial simulation results displayed, including the flux densities in the device and the cogging torque as the rotor position changes.

Fig 3. Motor simulation results in Altair FluxMotor.

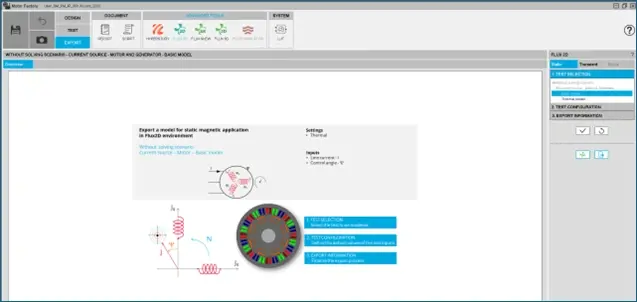

After we have completed our initial studies in Altair FluxMotor, we can begin the export process into Altair Flux; Figure 4 below shows that the device can be exported to the 2D, Skew (quasi-3D), or 3D version of Altair Flux, with each having different applications and default inputs. When choosing a specific module in which to export, the software will show you what kinds of simulations, outputs, and variables are available and customizable.

Fig 4. Export options in Altair FluxMotor.

As shown in Figure 5 below, exporting to Altair Flux 3D allows us to create a static magnetic application with customizable thermal settings, and we can control the line current and control angle as inputs in the Altair Flux 3D simulation.

Fig 5. Detailed Altair Flux 3D Export options in Altair FluxMotor.

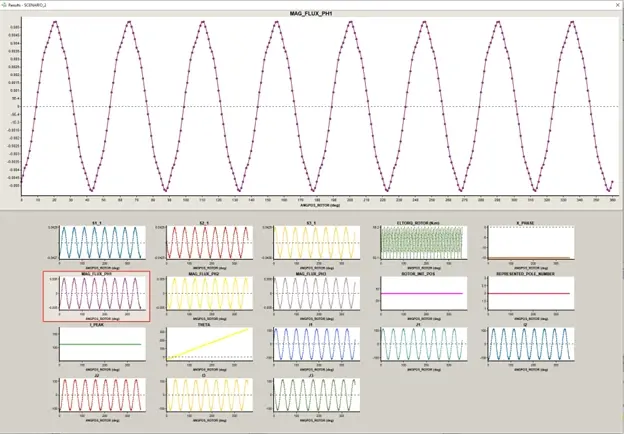

After exporting to Altair Flux, we have an entire new set of simulations available to us! For example, in Figure 6 below, I demonstrate several of the possible outputs as the control angle varies from 0 to 360 degrees. We can see the results for the current and magnetic flux in each phase, as well as the rotor torque, and several other measurements.

Fig 6. Initial various Altair Flux 3D results.

Additionally, we can create animations from our exported machine. Figure 7 shows a great depiction of how the motor was defined as a 3D device without the need for any three-dimensional CAD work. It also shows the results of the magnetic flux density throughout the entire device as the control angle goes through its entire range of possible values. We can see that Altair Flux offers multiple views of the device, including different angles and partial vs full device displays.

.gif)

Fig 7. Animated results of magnetic flux density in Altair Flux 3D.

Now you can successfully migrate from Altair FluxMotor to Altair Flux! This will allow you to vastly increase the efficiency of your motor design, analysis, and simulation, as this workflow allows engineers to completely customize rotating machines in 2D, quasi-3D, or 3D without the need for any manual modelling. This process also allows engineers to gain the best of two extremely powerful tools in the Altair suite of low frequency electromagnetic simulation, making a wide range of results easily attainable. If you have any questions about this process, about Altair FluxMotor or Altair Flux, or about any of the software in Altair’s portfolio of engineering solutions, please be sure to sure to reach out to us! As always, check out this blog routinely and subscribe to our YouTube channel for more content like this.