STEM Scholarship Winning Essay

TrueInsight is excited to announce the winner of the first TrueInsight STEM Scholarship. Check out the winning essay here.

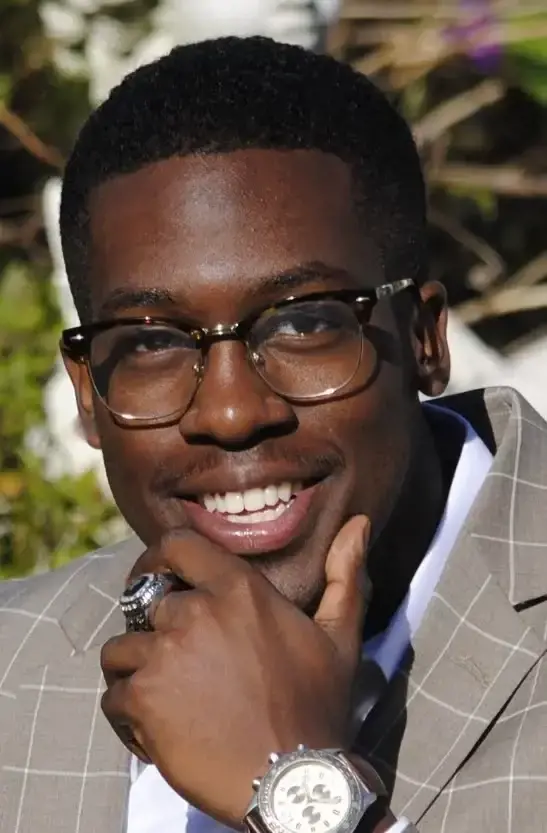

We are pleased to announce the winner of the first ever TrueInsight STEM Scholarship award to Austin Burns, of Morehouse College in Atlanta, GA. Austin is a Junior, Mechanical Engineering Major. We love Austin's passion for engineering and the advancement of technology.

"Engineers have a direct impact on the happiness of society and the people who make up that society...Engineers' main line of work is innovation, whether it is creating a whole new product or enhancing an already existing one. These technological advancements improve our quality of life by making it simpler, cozier, or more efficient."

To win this scholarship, students were asked to write an essay that answered the following question: With the use of Computer Aided Engineering (CAE) technology, what previous scientific ideas which seemed out of reach will become realized in the future?

Below is Austin's submission.

Computer-aided engineering (CAE) previously had a very narrow range of applications, mainly employed for cutting-edge research and development and other specialized jobs requiring simulation and optimization. The use of CAE has expanded significantly in the current period, and it is now frequently employed to speed up the entire process of product creation. Future CAE developments will make it possible to simulate ever-more complex designs while simultaneously speeding up the time it takes to bring a product to market.

It has become clear that simulating numerous situations is quite helpful in verifying and improving the design of different products. An excellent illustration is a fact that it is no longer required to repeatedly smash a sport utility vehicle into a barrier in order to examine the data. Instead, using powerful computers, engineers can simulate crashes and then make design changes to make the car safer.

It is simple to understand how a significant amount of money can be saved by simulating the entire procedure on a powerful computer rather than destroying a vehicle in several crash tests. As a result, the value of simulation has substantially grown, and it is now firmly moving in the direction of the beginning stages of design for a product.

It’s very commonplace for engineers to use CAE software for the purpose of creating initial designs, as well as for optimizing the product itself. Some of this optimization involves subtracting material from a potential outcome, so as to reduce its overall footprint while making no sacrifices regarding performance or strength. This has allowed CAE engineers to enhance performance as well as ergonomics, increase value and affordability, and produce products that are more energy-efficient and which are more sustainable.

It’s not an exaggeration to say that simulations such as these have been at the forefront of advancing product development timelines and that they have created all kinds of innovative designs for improving reliability and quality.

Because software tools have recently been developed that automate all the finest design principles and offer extensive analytical features, engineers may now concentrate on high-value jobs to a greater and greater extent. Instead of spending a lot of time entering data into a system and needing to validate any given model, adopting flexible workflow methods that speed up development and testing has considerably improved product engineering. Software engineers now have more time to innovate new products and build new features for ones that have a ready market.

Since the coronavirus epidemic is currently sweeping the globe, CAE has taken the lead in provide essential training for medical professionals so that diagnosis can be made rapidly and treatments can be given. One of the best examples of how CAE is assisting in this effort is through the development of a brand-new lung simulator that has been created to assist in instructing doctors on the methods typically employed in lung ultrasounds.

Lung imaging has already been put into practice on a global scale to assist in managing the Covid-19 virus patient treatment options. The CAE lung simulator allows students to practice their ultrasound imaging skills so they can diagnose many of the typical results because it exactly simulates many features of real human tissue.

Using this CAE imaging simulation, students can learn all about ultrasound system controls, applying PPE, recognition and understanding of coronavirus lung anatomy, and positioning and navigation between intercostal spaces. This is a lifesaving technology that can serve as the best available training tool for identifying coronavirus which has settled into a patient’s lungs. It has been developed so that it perfectly mimics each of the stages of the coronavirus disease as it affects a person’s lungs.

In the realm of CAE, there are undoubtedly some trends that are only getting started but that are anticipated to pick up steam and eventually find their way into standard CAE technology. The democratization of perpetual licenses, which are now sold by major CAE businesses, is one of them. Numerous CAE applications are already available for free or very close to being free. Many new solutions are starting to emerge that will enable consumers to pay as they go and utilize the tools from any location, regardless of the type of computer they are using.

System modeling with the use of CAE software is another approach that is quickly gaining ground. Currently, engineers frequently design and analyze pieces or assemblies, but designers and developers infrequently go as far as to study an entire system. Professionals in CAE will be able to test entire systems thanks to emerging technology, enabling analysis of the performance of the whole system. A situation where several discrete assemblies inside a car are tested using current methodologies might serve as an example. More testing will soon concentrate on examining outcomes from a complete automobile and its behavior under various circumstances.

Every time a new product design has been proposed in the past, and even in the majority of cases in the present, a new analysis has been required. Future CAE will eliminate a large portion of this wasted effort and enable engineers to collect data from other simulations and combine it with analytics to better understand the strengths and weaknesses of a design.

Multi-scale modeling, which offers the chance to utilize the same CAE software to model items at a molecular level as well as objects the size of a rocket ship, is one truly intriguing endeavor that is just starting to get popularity. The advantages of having such a capacity would include the ability to perform multi-scale modeling using the same software tool rather than having to perform two separate modeling efforts.

By: Austin W. Burns- Morehouse College